Table of Contents

Acrylic sheets have long been a preferred material for numerous applications due to their adaptability, durability, and unmatched clarity. Yet, many find themselves questioning why these sheets often come with a higher price tag compared to other plastic alternatives. This article delves into the factors behind the cost of acrylic sheets, their unique features, and why their pricing is justified by the value they bring. We’ll also explore additional benefits and answer some frequently asked questions to give you a comprehensive understanding of this versatile material.

The Manufacturing Process: A Key Cost Driver

One of the primary reasons acrylic sheets are more expensive lies in their intricate manufacturing process. Acrylic sheets are produced through the polymerization of methyl methacrylate (MMA) monomers, a multi-step process that requires:

1. Mixing and Preparation

High-quality raw materials are carefully combined to ensure consistency and clarity. Any impurities in this stage can compromise the final product’s performance.

2. Casting or Extrusion

The liquid mixture is poured into molds or processed through extrusion methods. The casting method, known for producing higher-quality sheets, is particularly labor-intensive and time-consuming.

3. Curing and Finishing

After casting, the material undergoes curing at controlled temperatures. This step solidifies the sheet, ensuring its durability and performance. Post-curing processes like cutting, polishing, and inspection add to production costs.

Because this process demands specialized equipment, precise control, and skilled technicians, the production costs of acrylic sheets are inherently higher than other types of plastics.

Performance Characteristics That Justify the Price

The superior performance features of acrylic sheets also contribute to their premium pricing. These features include:

1. Exceptional Optical Clarity

Acrylic sheets provide up to 92% light transmission, making them comparable to glass but far more lightweight and shatter-resistant. This clarity makes them ideal for displays, windows, and signage.

2. Weather and UV Resistance

Unlike many plastics that degrade under harsh environmental conditions, acrylic sheets maintain their appearance and structural integrity when exposed to sunlight and weather. Their resistance to UV radiation prevents yellowing, making them a reliable choice for outdoor use.

3. High Impact Resistance

Acrylic sheets are far more impact-resistant than traditional glass, reducing the risk of breakage. This makes them safer and more durable in applications where safety is a priority.

4. Ease of Fabrication

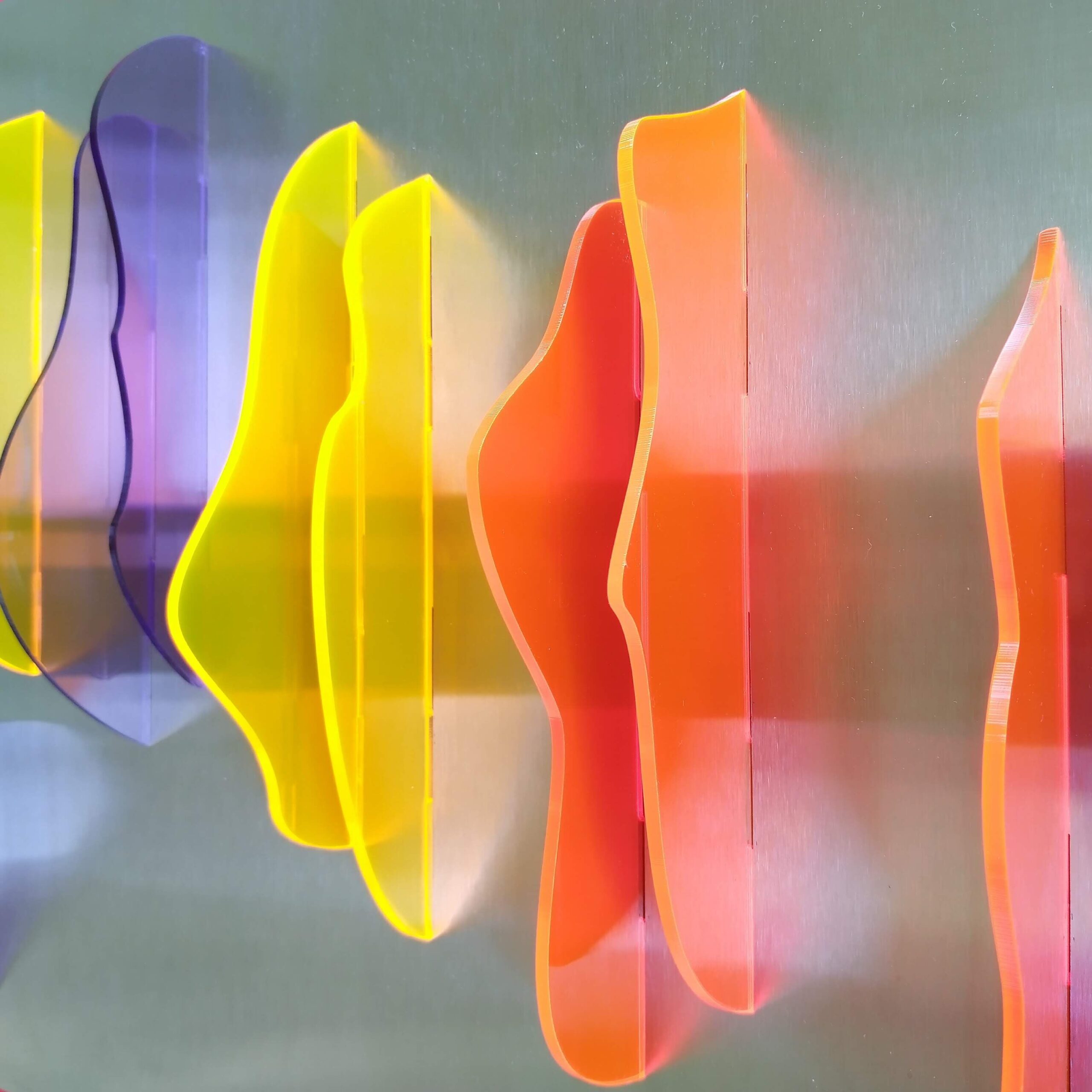

Acrylic sheets are highly versatile and can be easily cut, shaped, and thermoformed into complex designs without compromising their strength or clarity. This adaptability adds value but also requires precision during fabrication.

Increased Demand Across Industries

The growing demand for acrylic sheets in various industries is another factor that influences their cost. Some of the most common applications include:

- Automotive: Acrylic is used for headlight covers, dashboards, and interior components due to its lightweight and durability.

- Construction: Skylights, windows, and roofing often incorporate acrylic for its clarity and resistance to weathering.

- Signage and Displays: The retail and advertising sectors rely heavily on acrylic for eye-catching signs, displays, and protective barriers.

- Medical Equipment: During the COVID-19 pandemic, the demand for acrylic skyrocketed due to its use in protective barriers and shields.

With demand consistently high, manufacturers can maintain premium pricing due to the widespread utility and reliability of acrylic sheets.

Additional Features of Acrylic Sheets

In addition to their well-known characteristics, here are two additional features that enhance their value:

1. Sustainability in Production

Modern advancements in acrylic manufacturing now allow for recycling and repurposing of acrylic waste. Recycled acrylic retains many of the original properties, making it an environmentally friendly choice for companies prioritizing sustainability.

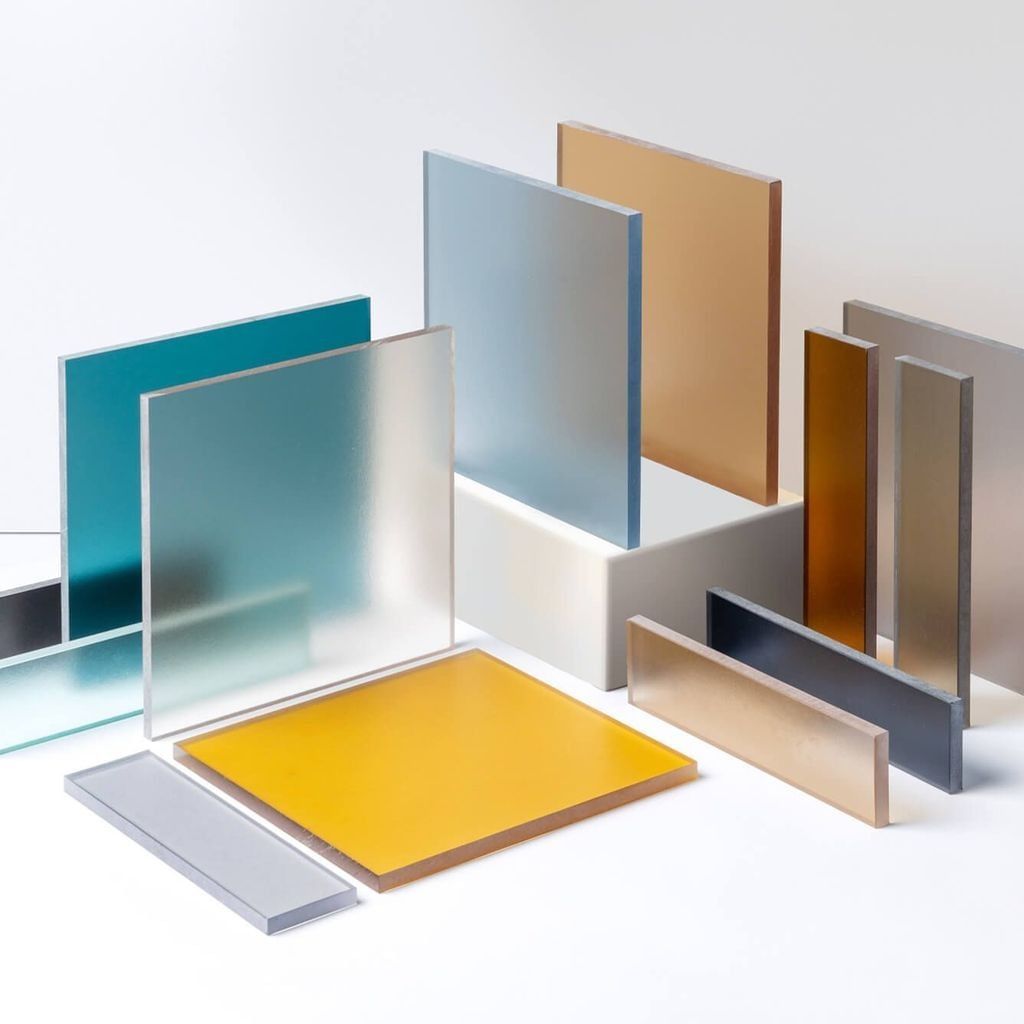

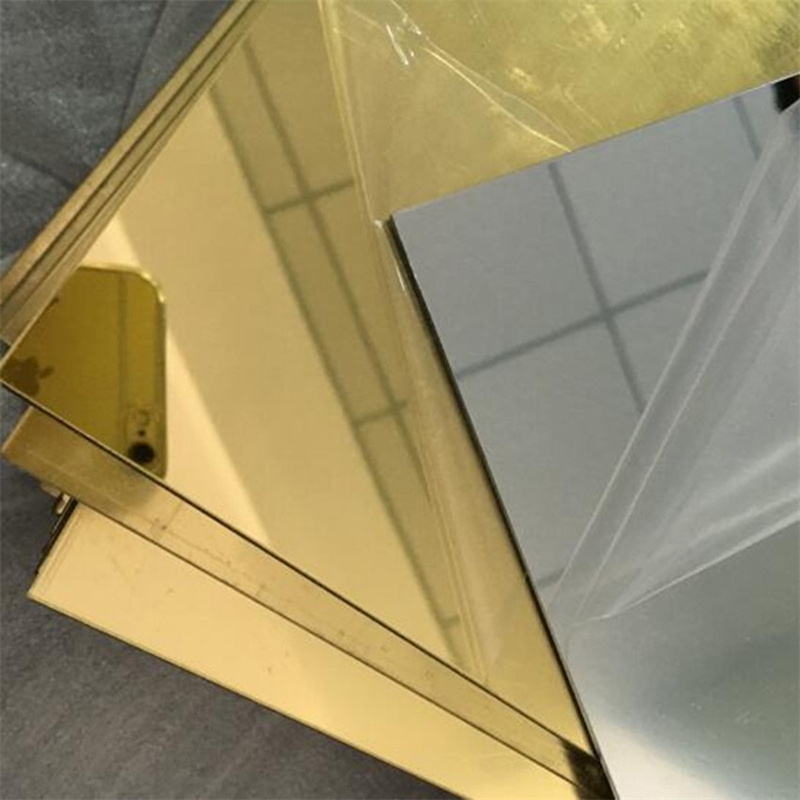

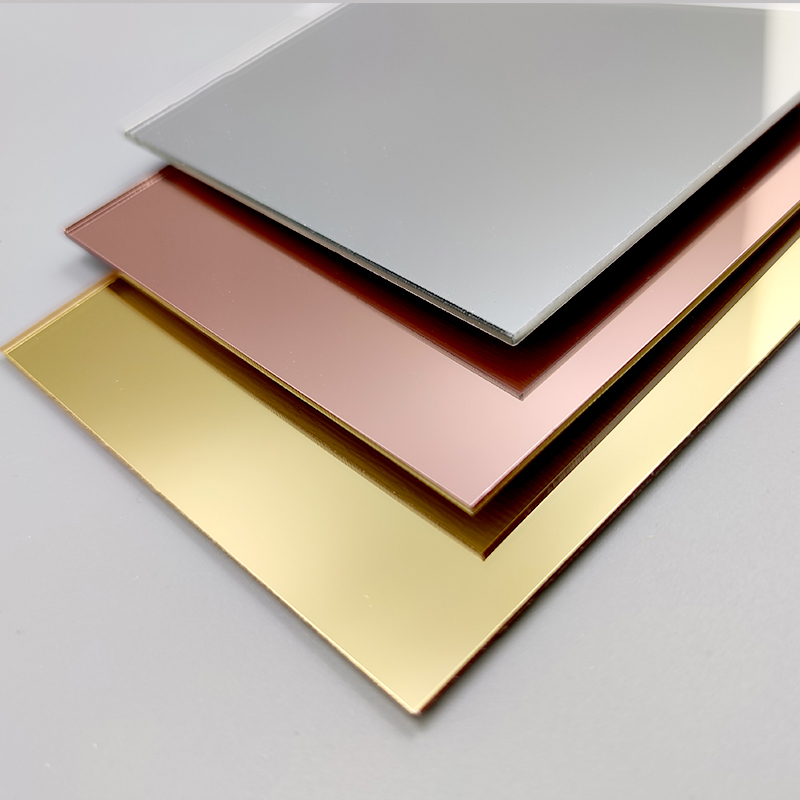

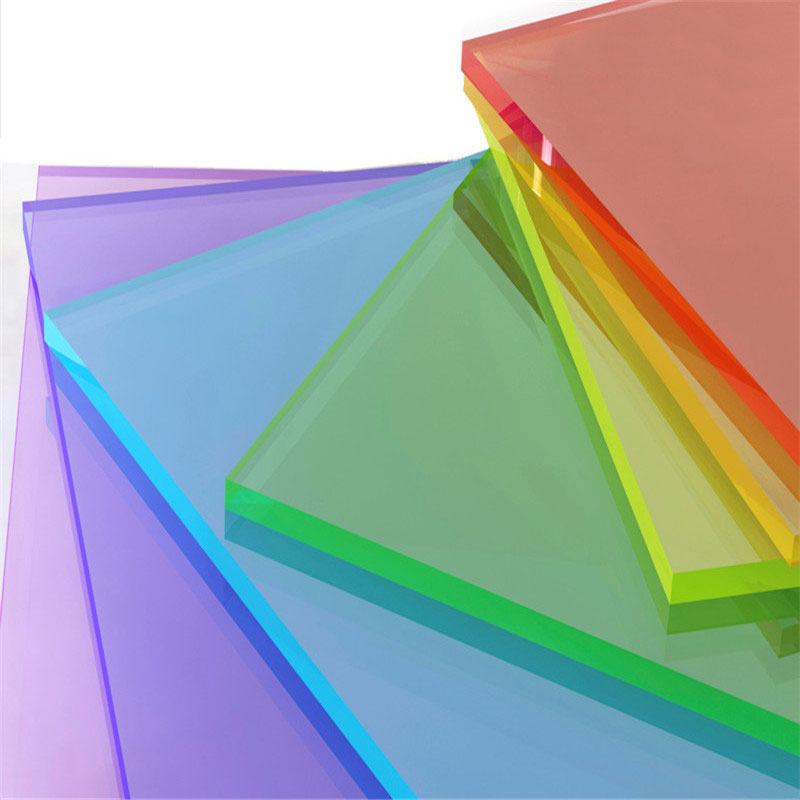

2. Color and Texture Customization

Acrylic sheets are available in a wide variety of colors, finishes, and textures, catering to both functional and aesthetic needs. Whether you need a frosted sheet for privacy or a vibrant, colored sheet for branding, acrylic offers unparalleled design flexibility.

The ASM Plastic Advantage

At ASM, we recognize the importance of offering premium acrylic sheets without compromising affordability. Our state-of-the-art facilities and skilled technicians ensure every sheet meets the highest standards of quality, clarity, and durability. Whether you need sheets for commercial, industrial, or personal projects, we provide a wide range of options tailored to your specific needs.

Our commitment extends beyond product quality—we also pride ourselves on exceptional customer service. From assisting with product selection to providing detailed guidance on installation and care, we aim to make your experience seamless.

Conclusion

While acrylic sheets may initially seem expensive, their cost is justified by their superior performance, durability, and versatility. From their complex manufacturing process to their widespread demand across industries, the value they provide far outweighs their price. With added benefits like sustainability and customization, acrylic sheets remain an excellent investment for countless applications.

If you’re looking for high-quality acrylic sheets at competitive prices, ASM is your trusted partner. Reach out today to explore our offerings and let us help you find the perfect solution for your project.

FAQs About Acrylic Sheets

1. Are acrylic sheets stronger than glass?

Yes, acrylic sheets are up to 17 times more impact-resistant than traditional glass. While they may scratch more easily, their strength and durability make them a safer alternative in many applications.

2. How do I maintain and clean acrylic sheets?

To clean acrylic sheets, use a soft microfiber cloth and a mild soap or specialized acrylic cleaner. Avoid abrasive materials or ammonia-based products, as these can cause scratches or clouding.

3. Why is cast acrylic more expensive than extruded acrylic?

Cast acrylic offers superior clarity, thickness uniformity, and overall quality compared to extruded acrylic. Its more labor-intensive production process makes it more expensive but often worth the investment for high-end applications.