Table of Contents

When selecting materials for specific projects, PVC (Polyvinyl Chloride) and Acrylic (Polymethyl Methacrylate) are two of the most commonly used plastic sheets. These versatile materials have broad applications across multiple industries, but their differences make them suitable for different purposes. In this article, we’ll break down the key characteristics of both materials, compare their performance in various aspects, and help you choose the right material for your next project.

The Basics: What Are PVC and Acrylic?

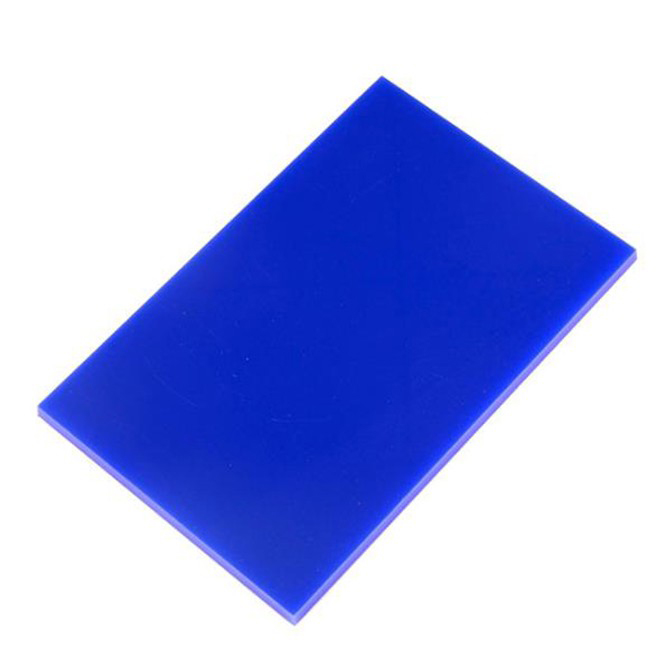

PVC is a thermoplastic polymer widely known for its affordability and practicality. It’s often used in construction materials, plumbing, signage, and many more sectors where cost-effectiveness is crucial. PVC provides strong rigidity, weather resistance, and easy machinability at a low price point. However, its optical clarity and aesthetic appeal are less impressive compared to acrylic.

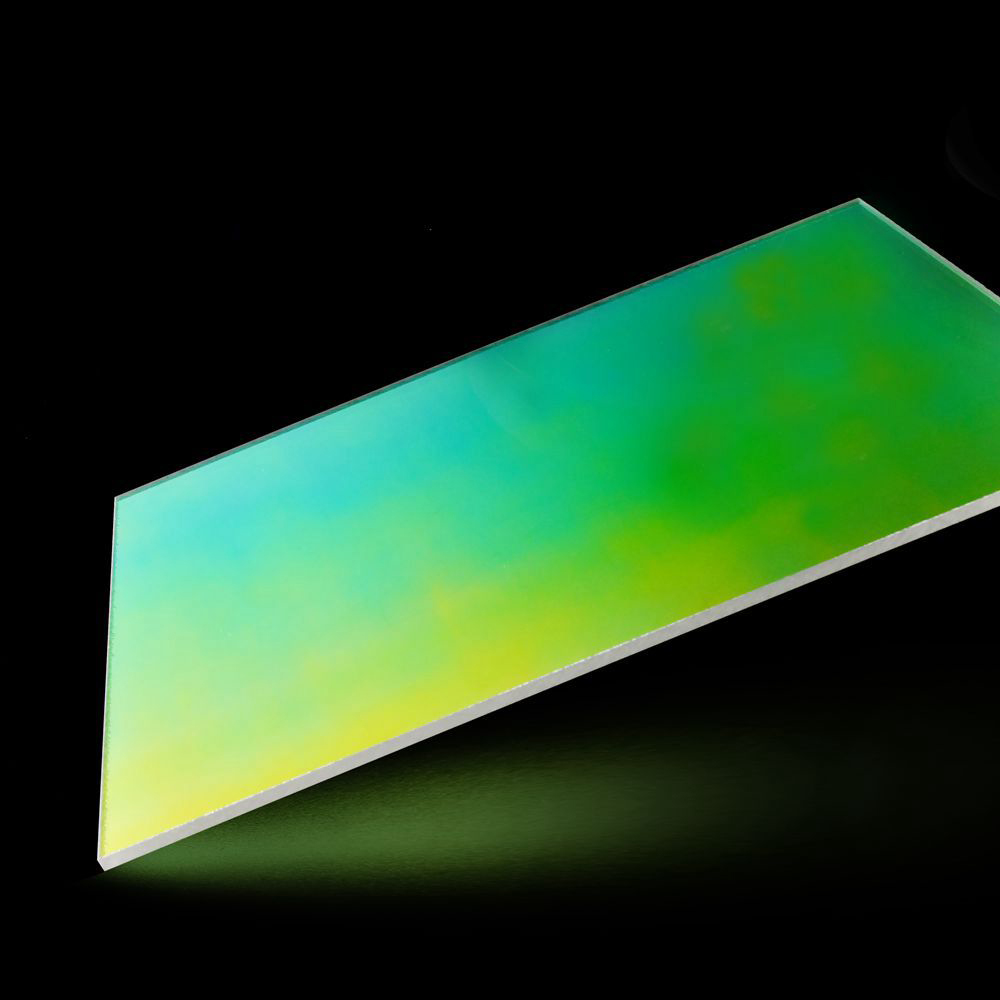

Acrylic, made from polymethyl methacrylate (PMMA), is a superior plastic when it comes to transparency, aesthetics, and resistance to UV degradation. Acrylic sheeting allows light to pass through almost as clearly as glass, making it a popular choice for applications requiring high visibility. It is often found in areas where both form and function are essential, such as in display cases, windows, and signs.

Key Comparisons: PVC vs Acrylic

Below is a detailed breakdown of the strengths and weaknesses of each material based on different factors:

| Factor | PVC | Acrylic |

|---|---|---|

| Durability | Moderate impact resistance, weatherable | Excellent impact resistance, UV-resistant, long-lasting |

| Optical Clarity | Cloudy, less clear | Crystal clear, almost like glass |

| Cost | Affordable ($5 – $15 per sq ft) | Expensive ($15 – $50+ per sq ft) |

| Flexural Strength | Moderate | High, more resistant to bending |

| Chemical Resistance | Excellent for chemicals, oils, and acids | Less resistant, more suited for aesthetic applications |

| Weather Resistance | Fair | Excellent, doesn’t yellow easily |

| Fabrication | Easier to machine, chemical welding possible | Requires care when cutting or drilling |

| Recyclability | High, easily recyclable | Less recyclable compared to PVC |

Durability: Which Material Lasts Longer?

When considering materials for long-term applications, durability is crucial. Acrylic excels in terms of impact resistance, UV stability, and its overall ability to withstand harsh environmental conditions. It is highly resistant to weathering, which makes it an ideal choice for outdoor uses like skylights, signs, and display cases exposed to the elements. Acrylic maintains its clarity and strength for many years without degrading, unlike PVC, which can become brittle with exposure to UV light and outdoor conditions.

Acrylic’s impact resistance is another major advantage. Unlike glass, it is shatterproof, and its ability to resist cracks from minor impacts makes it a popular choice for protective screens, signage, and displays. PVC, on the other hand, is more flexible and absorbs impact better, but it may suffer from more permanent damage when subjected to harsh forces.

Optical Clarity: Acrylic Outshines PVC

Acrylic is the clear winner when it comes to optical clarity. Acrylic sheeting offers a level of transparency that is comparable to glass, allowing it to transmit up to 92% of visible light. This makes it perfect for applications where clarity is essential, such as windows, display cases, and aquariums. In contrast, PVC is often cloudy or opaque, making it unsuitable for applications that require clear visibility.

Additionally, acrylic maintains its visual clarity over time. It does not yellow, crack, or degrade under UV exposure like PVC. This makes acrylic a superior option for applications that require long-term aesthetic appeal, such as in museums, art displays, and retail environments.

Cost: The Economic Choice

PVC is typically more affordable than acrylic, making it a better option when working with a limited budget. On average, PVC costs between $5 and $15 per square foot, depending on the grade and thickness. Acrylic, in contrast, tends to be more expensive, ranging from $15 to $50 per square foot, depending on the quality and features, such as UV resistance or abrasion resistance.

While acrylic may require a higher initial investment, its longer lifespan and durability can make it the more cost-effective option in the long run. Acrylic retains its clarity and strength far longer than PVC, which tends to degrade and become brittle when exposed to the sun and weather.

Impact and Flexural Strength: Acrylic for Long-Term Performance

Acrylic offers superior flexural strength compared to PVC. This means acrylic is more resistant to bending under stress and can support more weight without warping. PVC, while more flexible, may bend under heavy loads, making it unsuitable for structural applications where rigidity is essential.

In terms of tensile strength, acrylic outperforms PVC as well. Tensile strength refers to a material’s resistance to being pulled apart, and acrylic’s higher tensile strength makes it less prone to breakage under tension. This is particularly important in applications such as protective screens, signage, and structural components.

Chemical Resistance: PVC’s Advantage in Harsh Environments

One area where PVC outshines acrylic is in its resistance to chemicals. PVC is highly resistant to acids, oils, alcohols, and salts, making it a go-to material for plumbing, industrial applications, and construction materials. It can withstand exposure to harsh chemicals without deteriorating, which is why it is often used in pipes, window frames, and roofing where chemical exposure is common.

Acrylic, on the other hand, is not as chemically resistant as PVC. While it can handle certain chemicals, it is more vulnerable to degradation when exposed to harsh acids or solvents. Acrylic is best suited for applications where aesthetics and optical clarity are the priority, such as in signage and display cases, rather than for environments exposed to chemicals.

Environmental Impact: Sustainability and Recycling

One of the primary benefits of PVC is its recyclability. PVC can be recycled multiple times without losing its strength or structural properties, making it a sustainable choice for many industries. Unlike other plastics, PVC does not degrade significantly with recycling, and its longevity in construction and industrial applications reduces the need for frequent replacements, further minimizing waste.

Acrylic, however, is more challenging to recycle. Although it can be processed in certain facilities, it’s not as widely accepted for recycling as PVC. As a result, PVC may have a lower environmental impact overall when considering its lifecycle and recyclability.

Fabrication and Machinability: Ease of Use

Both PVC and acrylic can be easily fabricated using standard tools such as saws, drills, and routers. Acrylic, however, requires more care during machining to avoid cracking or excessive heat buildup. It is more difficult to weld, but its clear surface allows for intricate designs, making it ideal for high-precision applications.

PVC is easier to machine and weld compared to acrylic, as it is more forgiving in terms of processing. It’s also less prone to cracking, allowing for faster and more efficient fabrication.

Conclusion: PVC or Acrylic – Which Material Should You Choose?

Choosing between PVC and acrylic ultimately depends on your specific project requirements. Both materials have distinct advantages, and understanding the key differences can help you make an informed decision.

- Acrylic is best for applications requiring high optical clarity, UV resistance, and long-term durability, such as skylights, display cases, and signage.

- PVC is an ideal choice for projects where chemical resistance, cost-effectiveness, and ease of fabrication are the priority. It is commonly used in construction, plumbing, and industrial applications.

By considering factors such as cost, durability, clarity, and specific application needs, you can confidently select the material that best suits your project.

FAQs

1. Is acrylic more expensive than PVC?

Yes, acrylic typically costs more than PVC. However, the higher price is justified by its superior optical clarity, durability, and resistance to UV degradation.

2. Can acrylic be used outdoors?

Yes, acrylic is highly suitable for outdoor applications due to its excellent weather resistance and UV stability. It maintains its clarity and strength even after prolonged exposure to the elements.

3. What are the main advantages of PVC?

PVC is known for its affordability, ease of fabrication, and chemical resistance. It is an excellent choice for plumbing, construction, and applications where chemical exposure is a concern.