Table of Contents

Acrylic sheets are versatile materials used across various industries, including construction, transportation, and interior design. Their popularity stems from their lightweight nature, durability, and exceptional clarity. As an alternative to glass, acrylic sheets provide unique advantages that make them an indispensable choice for numerous applications. This article explores the many benefits of acrylic sheets, shedding light on their practical uses and innovative properties.

Lightweight and Easy to Handle

Acrylic sheets are significantly lightweight, weighing up to 50% less than traditional glass. This feature makes them easy to transport, install, and handle, especially in situations where glass would be too heavy. From intricate crafting projects to large installations, the lightweight nature of acrylic sheets reduces stress on surrounding structures and simplifies the process.

Safety First: Shatter Resistance

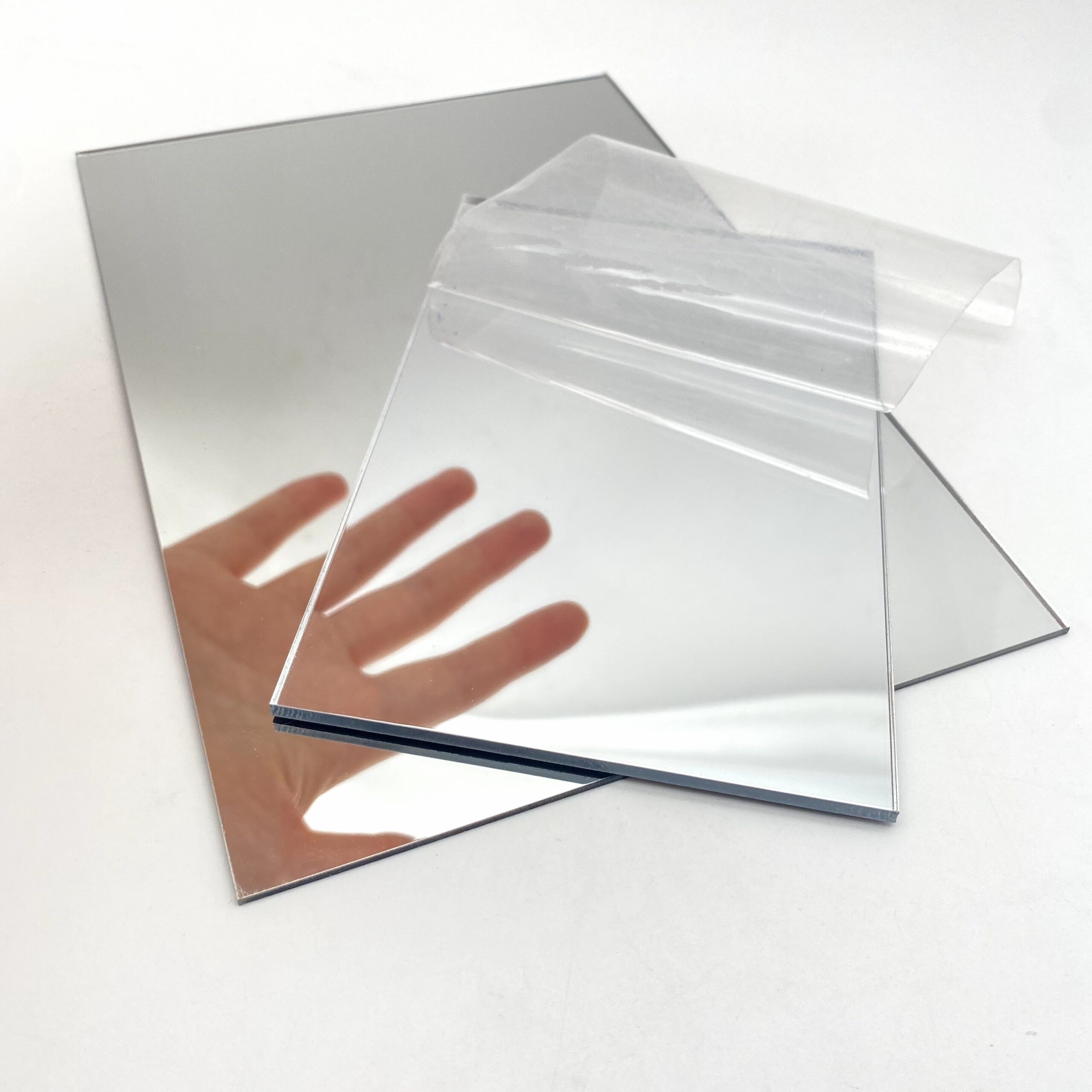

Compared to glass, acrylic sheets are highly shatter-resistant. When subjected to pressure or impact, acrylic sheets are less likely to break into sharp shards. This makes them an ideal choice for environments with safety concerns, such as homes with children, schools, or public spaces. Acrylic mirror sheets also provide a safer, lightweight alternative to traditional mirrors.

Cost-Effective Solution

Acrylic sheets are typically 50% cheaper than glass, making them an economical material choice. Lower production costs, lightweight design, and easy fabrication contribute to their affordability, making them accessible to both hobbyists and professionals.

Exceptional Transparency

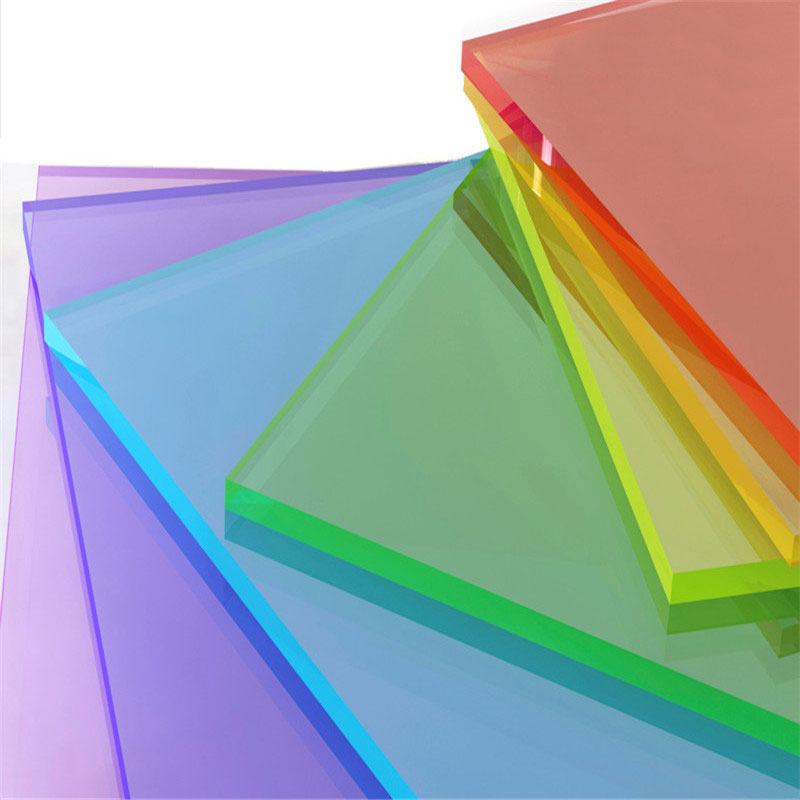

Acrylic sheets are renowned for their high light transmission, ranging between 92% and 98%, depending on thickness. This outstanding optical clarity makes them ideal for projects requiring excellent visibility, such as signage, aquarium panels, and protective screens. Acrylic sheets often surpass glass in transparency, providing a crystal-clear view for various applications.

Easy to Fabricate

A standout feature of acrylic sheets is their flexibility in fabrication. They can be easily cut, shaped, and drilled using standard tools like saws, cutters, and heat guns. With a low melting point, acrylic allows for thermal welding and cold-forming, enabling intricate designs with minimal effort. Whether creating small display cases or large architectural façades, acrylic sheets can be customized to meet specific needs.

Weather Resistance for Outdoor Use

Acrylic sheets have excellent weather resistance, enduring rain, snow, and extreme temperatures without cracking or becoming brittle. This durability makes them ideal for outdoor installations like skylights, carports, and greenhouses, where long-term performance is essential.

UV Resistance for Longevity

Acrylic sheets are naturally resistant to UV rays, preventing discoloration and degradation over time. Unlike some materials requiring additional coatings, acrylic effectively blocks UV rays, ensuring clarity and durability even after years of sun exposure. This quality makes them perfect for outdoor signage, windows, and protective covers.

High Impact Resistance

Acrylic sheets are far more impact-resistant than glass, making them suitable for areas with frequent use or occasional impacts. In schools, offices, or homes, acrylic sheets can withstand accidental hits from objects like balls, books, or furniture without cracking or breaking.

Heat Resistance and Insulation

Acrylic sheets offer moderate heat resistance, making them suitable for environments with temperature fluctuations. While not as heat-resistant as polycarbonate, acrylic sheets maintain structural integrity over a wide temperature range. Additionally, their thermal insulation properties help reduce heat transfer, improving energy efficiency in skylights, windows, and similar applications.

Lightweight Sound Insulation

Acrylic sheets provide a degree of sound insulation, making them ideal for offices, recording studios, and residential spaces. They reduce noise effectively while maintaining a sleek appearance. Their lightweight nature also simplifies installation compared to heavier soundproofing materials.

Chemical Resistance

Acrylic sheets exhibit excellent resistance to many chemicals, including acids, alkalis, and cleaning agents. This makes them ideal for laboratories, industrial settings, and environments where chemical exposure is frequent. Their chemical resistance ensures long-term reliability in demanding applications.

Applications of Acrylic Sheets

Acrylic sheets are widely used across various industries due to their versatility and practicality. Common applications include:

- Signage and Displays: High transparency and weather resistance make them perfect for advertising and informational displays.

- Protective Barriers: Frequently used in retail stores, offices, and healthcare settings as sneeze guards and shields.

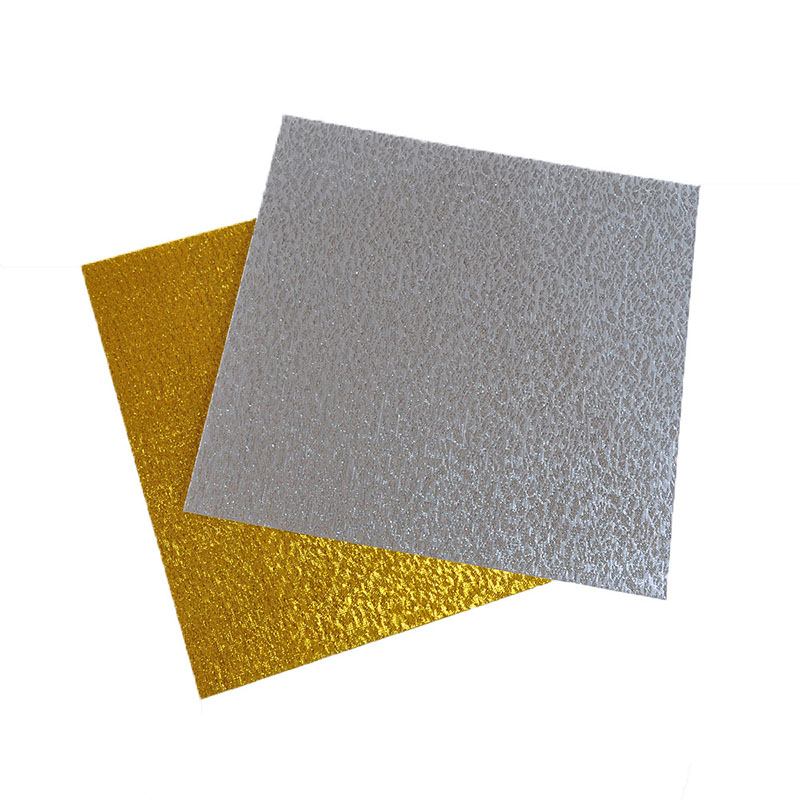

- Furniture and Decor: Ideal for creating modern, minimalist furniture and decorative elements.

- Construction: Widely used for skylights, windows, and partitions due to their strength and clarity.

- Aquariums and Tanks: Their transparency and durability make them perfect for aquariums and water tanks.

- Crafting and DIY Projects: Loved by hobbyists for creating decorative items, jewelry, and more.

Conclusion

Acrylic sheets are a versatile, cost-effective, and durable material suitable for various indoor and outdoor projects. Their lightweight nature, exceptional clarity, and resistance to weather and UV light make them a reliable choice for construction, design, and crafting. By understanding their advantages and properties, you can make informed decisions and explore endless creative possibilities. With growing customization options, acrylic sheets are becoming an essential material for professionals and hobbyists alike.