Mundarija

Acrylic sheets, particularly in the standard 4×8 feet (1220mm x 2440mm) size, are widely utilized across various industries due to their versatility, durability, and clarity. Understanding the cost of these sheets involves considering several factors, including material thickness, quality, supplier pricing, and even sourcing directly from manufacturers. This article delves into the determinants of acrylic sheet pricing, provides a comparative analysis of current market prices in the UK, and includes insights into sourcing from ASM factories to help buyers make more informed decisions.

Factors Influencing the Cost of a 4×8 Acrylic Sheet

The price of a 4×8 acrylic sheet is influenced by multiple factors:

1. Thickness of the Sheet

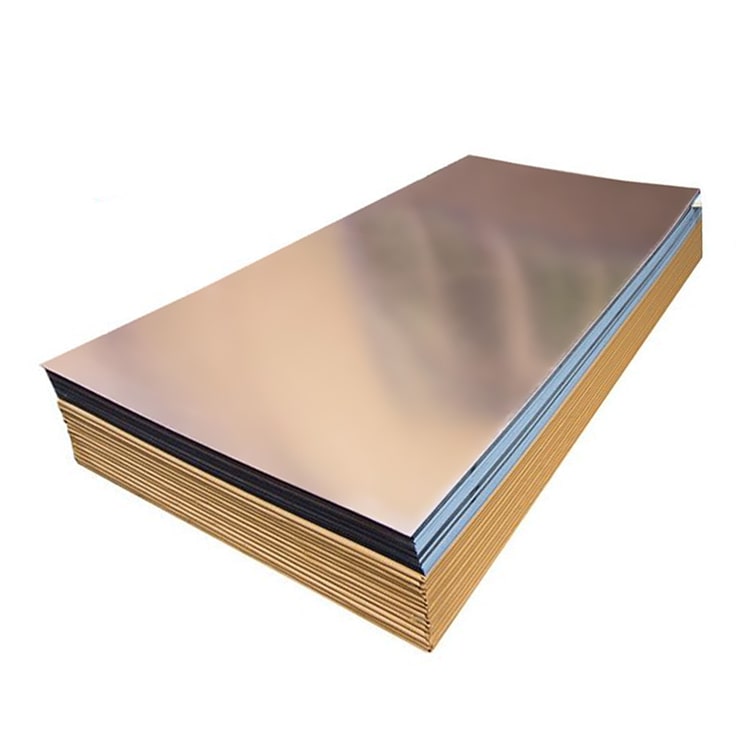

Acrylic sheets come in various thicknesses, typically ranging from 2mm to 20mm. Thicker sheets require more material, thereby increasing the cost. For instance, a 4mm thick sheet will generally be less expensive than an 8mm thick sheet of the same dimensions.

2. Type of Acrylic

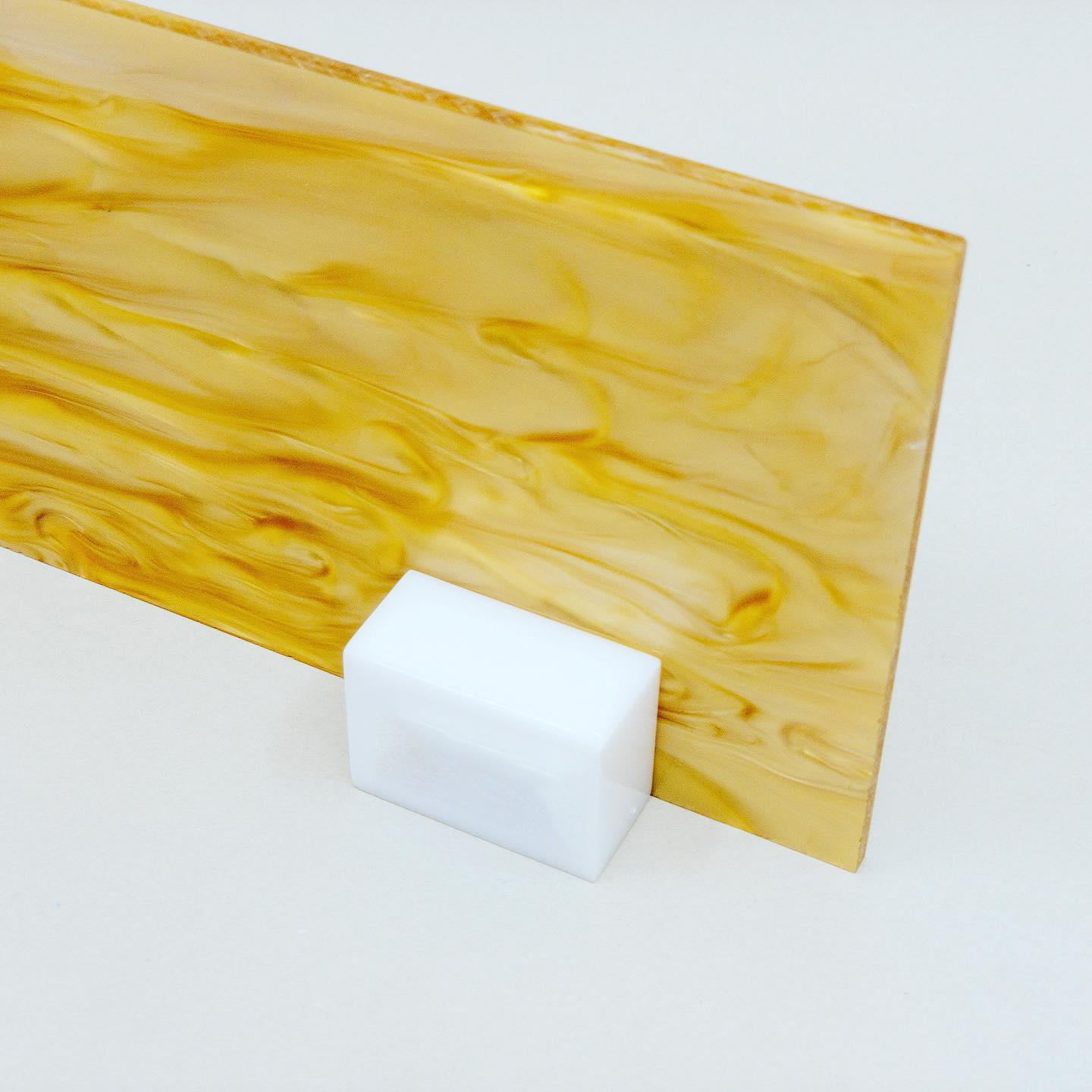

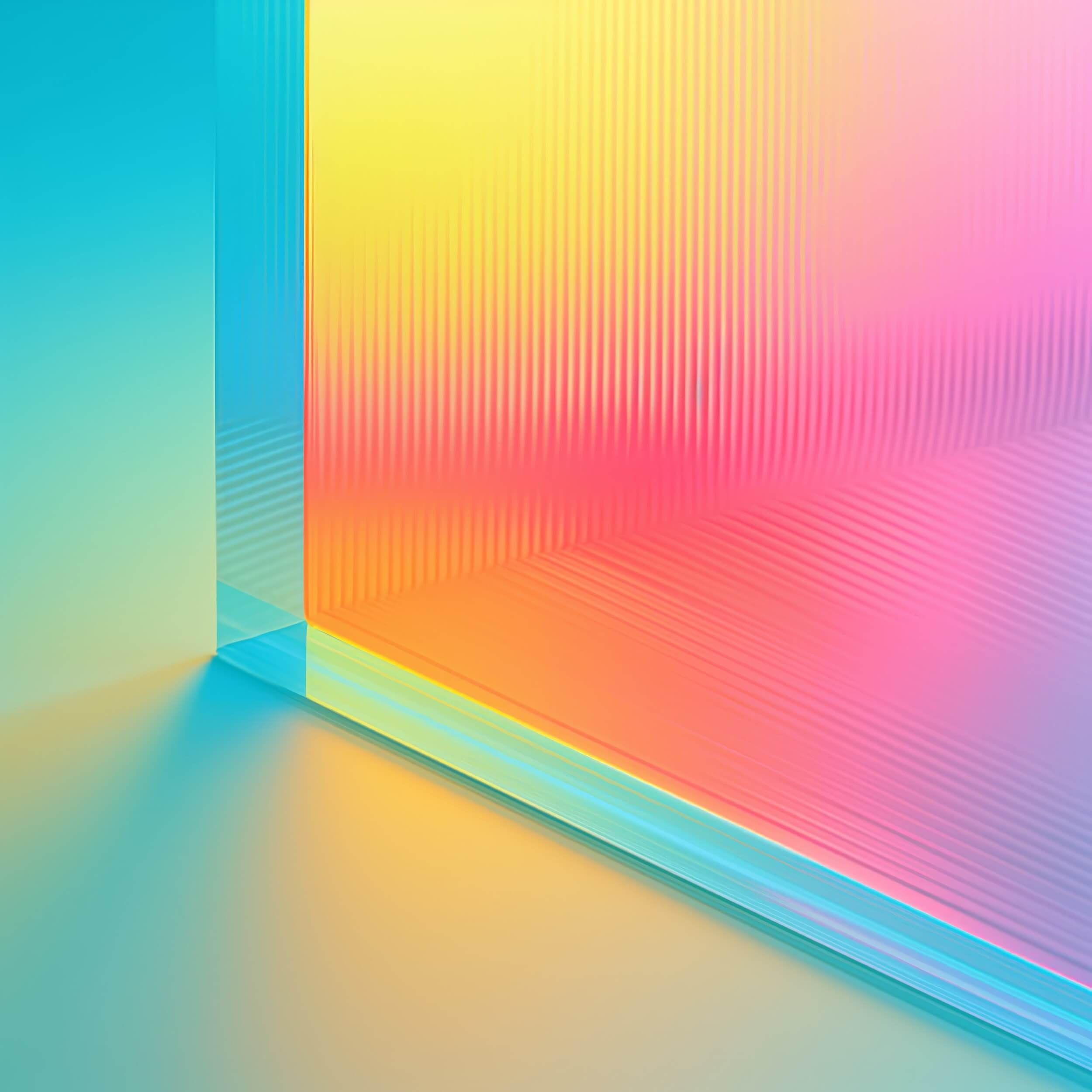

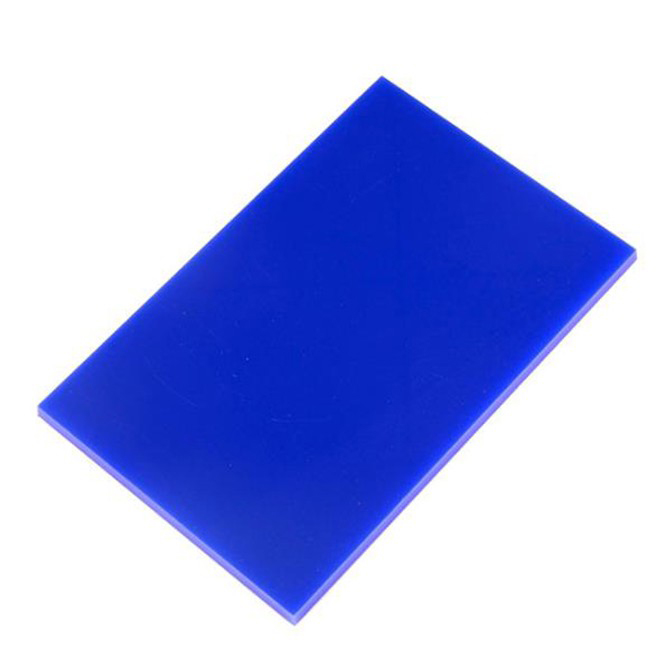

There are primarily two types of acrylic sheets: cast and extruded. Cast acrylic tends to be of higher quality with better optical clarity and greater resistance to solvents, making it more expensive than extruded acrylic.

3. Quality and Brand

Premium brands or those offering enhanced features, such as UV resistance or scratch-resistant coatings, may command higher prices.

4. Supplier and Quantity

Prices can vary between suppliers, and purchasing in bulk often results in discounted rates.

5. Direct Factory Sourcing (ASM)

ASM (Asian Sourcing Manufacturers) factories are often located in regions like China and Southeast Asia, offering competitive factory-direct pricing for bulk orders. By bypassing traditional distributors and purchasing directly from these manufacturers, buyers can achieve substantial cost savings, especially for large projects.

Comparative Analysis of Market Prices in the UK and ASM Factories

Below is a table summarizing the current market prices for 4×8 acrylic sheets from top suppliers in the UK, along with typical factory pricing from ASM manufacturers (as of January 2025):

| Supplier/Factory | Product Description | Price (Excl. VAT) | Features | Website |

|---|---|---|---|---|

| Plastic Experts | 4mm shaffof akril plita (2440mm x 1220mm) | £82.50 | High durability, clarity | Visit Site |

| Wickes | Durable clear acrylic sheet (approx. 4×8) | £150–£200 (estimated) | General-purpose use | Visit Site |

| Acrylics Online | 4mm clear acrylic, cut-to-size | From £56.67 | Custom size options | Visit Site |

| ASM Manufacturer (China) | 4mm cast acrylic sheet | $20–$35 (£16–£28) | High clarity, bulk discounts | Factory sourcing required |

| ASM Manufacturer (Vietnam) | 4mm extruded acrylic sheet | $15–$25 (£12–£20) | Cost-effective, quick production | Factory sourcing required |

| The Acrylic Warehouse | Custom acrylic sheet (cut-to-size) | From £60 | Tailored to exact needs | Visit Site |

Eslatma: ASM factory prices are estimated for bulk orders (minimum quantity often 50 sheets or more) and exclude shipping costs, import duties, and customs fees.

Why Consider ASM Factories for Acrylic Sheets?

- Cost Efficiency: ASM factories often offer significant savings, particularly for large orders. Prices for standard 4×8 sheets can be as low as £12–£28 depending on the material type and thickness.

- Custom Specifications: Many ASM manufacturers provide extensive customization options, including specific dimensions, colors, finishes, and coatings (e.g., UV resistance).

- Global Shipping Options: Most ASM factories are experienced in exporting worldwide, offering cost-effective shipping solutions for bulk purchases.

- Scalability for Large Projects: For construction, signage, or industrial applications requiring large volumes of acrylic sheets, sourcing directly from ASM manufacturers can ensure a consistent supply at competitive prices.

Applications and Benefits of Acrylic Sheets

Acrylic sheets are incredibly versatile and find applications across numerous industries. Below are some expanded use cases and their associated benefits:

1. Industrial Applications

- Signage and Advertising: Acrylic’s high clarity and durability make it ideal for creating eye-catching signs, lightboxes, and display boards.

- Construction: Used as lightweight, shatter-resistant alternatives to glass for windows, skylights, and protective barriers. Its weather-resistant properties make it suitable for outdoor use.

- Automotive and Aviation: Commonly used in windshields, instrument panels, and lighting covers due to its high impact resistance and light weight.

2. Residential and Decorative Uses

- Furniture: Acrylic sheets are often used in modern furniture designs, such as coffee tables, bookshelves, and chairs, offering a sleek, contemporary aesthetic.

- Home Décor: Frosted or colored acrylic adds a sophisticated touch to partitions, wall art, and lighting fixtures.

- DIY Projects: Popular for crafting projects like photo frames, terrariums, and organizers due to its ease of cutting and shaping.

3. Retail and Commercial Applications

- Point-of-Sale Displays: Acrylic is widely used in display cases, brochure holders, and countertop stands to showcase products in retail environments.

- Exhibition and Trade Shows: Lightweight and easy to transport, acrylic sheets are perfect for temporary structures, branding walls, and product showcases.

4. Medical and Protective Equipment

- Protective Barriers: Frequently used as transparent shields in offices, retail stores, and hospitals to ensure safety and hygiene.

- Medical Devices: Found in laboratory equipment, incubators, and display cases for medical instruments due to its non-toxic and easy-to-clean nature.

5. Eco-Friendly Benefits

Modern recycling technologies allow acrylic to be reused, reducing waste and making it an environmentally friendly option for many applications.

Tips for Choosing the Right Acrylic Sheet

When selecting an acrylic sheet for your project, several factors must be considered to ensure the best results:

- Determine Project Requirements: Thickness: For structural projects like partitions, thicker sheets (6mm and above) are recommended, while thinner sheets (2mm–4mm) suffice for decorative or protective overlays.

- Compare Suppliers and Factories: Local Suppliers: Offer faster delivery times and easier returns for smaller projects. ASM Factories: Ideal for bulk purchases or customized solutions, but require consideration of shipping, import duties, and lead times.

- Request Samples: Always request samples to inspect the clarity, finish, and overall quality, especially when sourcing from ASM factories or unfamiliar suppliers.

- Factor in Costs Beyond the Sheet: Additional Services: Costs for cutting, polishing, or engraving should be factored into the budget. Shipping and Import: When sourcing from overseas, include freight costs, customs duties, and potential delays.

- Check Certifications and Standards: For safety-critical applications, ensure the acrylic sheet complies with ISO, CE, or other relevant standards for durability, fire resistance, and UV stability.

Additional Buying Tips for ASM Factory Sourcing

- Understand Minimum Order Quantities (MOQ): ASM factories often require a minimum purchase of 50 sheets or more, making them better suited for bulk buyers or large-scale projects.

- Communicate Clearly with the Factory: Provide detailed specifications, including dimensions, thickness, color, and any special coatings (e.g., anti-glare, UV protection). Confirm lead times, as production and shipping can take several weeks.

- Inspect Quality Assurance Procedures: Request documentation on quality assurance processes, including batch testing and certifications. This is especially important for structural or safety-critical applications.

- Work with a Freight Forwarder: For large orders, using a professional freight forwarder can simplify the logistics of shipping and customs clearance, ensuring timely delivery.

- Negotiate for Long-Term Partnerships: If you foresee regular purchases, establish a long-term relationship with the manufacturer for better pricing, faster production, and priority service.

Xulosa

The cost of a 4×8 acrylic sheet in the UK typically ranges from £80 to £200, while sourcing directly from ASM factories offers significantly lower prices, ranging from £12 to £28 per sheet for bulk orders. By understanding the various factors influencing pricing, such as thickness, type, and supplier, buyers can make informed decisions that align with their project requirements.

Whether sourcing locally for convenience or internationally for cost savings, it’s essential to evaluate options carefully, consider additional costs, and request samples when necessary. Acrylic sheets remain a versatile and reliable material for a wide range of applications, offering a balance of durability, clarity, and cost-efficiency.

By leveraging the insights provided in this article, you can confidently choose the best acrylic sheet solution for your needs, optimize your budget, and ensure the success of your project.