Mundarija

Acrylic sheets, commonly referred to as Plexiglass or acrylic glass, are a versatile and durable material used in a wide range of industries. From signage to automotive and interior design, acrylic sheets provide clarity, strength, and flexibility. However, with numerous options available in terms of size, thickness, finish, and color, choosing the right acrylic sheet for your project can be a daunting task. In this guide, we will explore key factors to consider when selecting acrylic sheets, helping you make an informed decision that meets your specific needs.

Introduction

Acrylic sheets are one of the most popular materials used for both functional and decorative purposes. Their light weight, high clarity, and easy fabrication make them suitable for various applications, from protective barriers and signage to furniture and custom designs. However, there is no one-size-fits-all solution when it comes to choosing acrylic sheets. The right choice depends on factors like intended use, environmental conditions, and design preferences.

This comprehensive guide will delve into the factors you should consider when choosing acrylic sheets, helping you select the right type for your project. We’ll also highlight key differences between cast and extruded acrylic, explore the various finishes available, and discuss the importance of durability and UV resistance for long-term use.

Understanding Acrylic Sheets

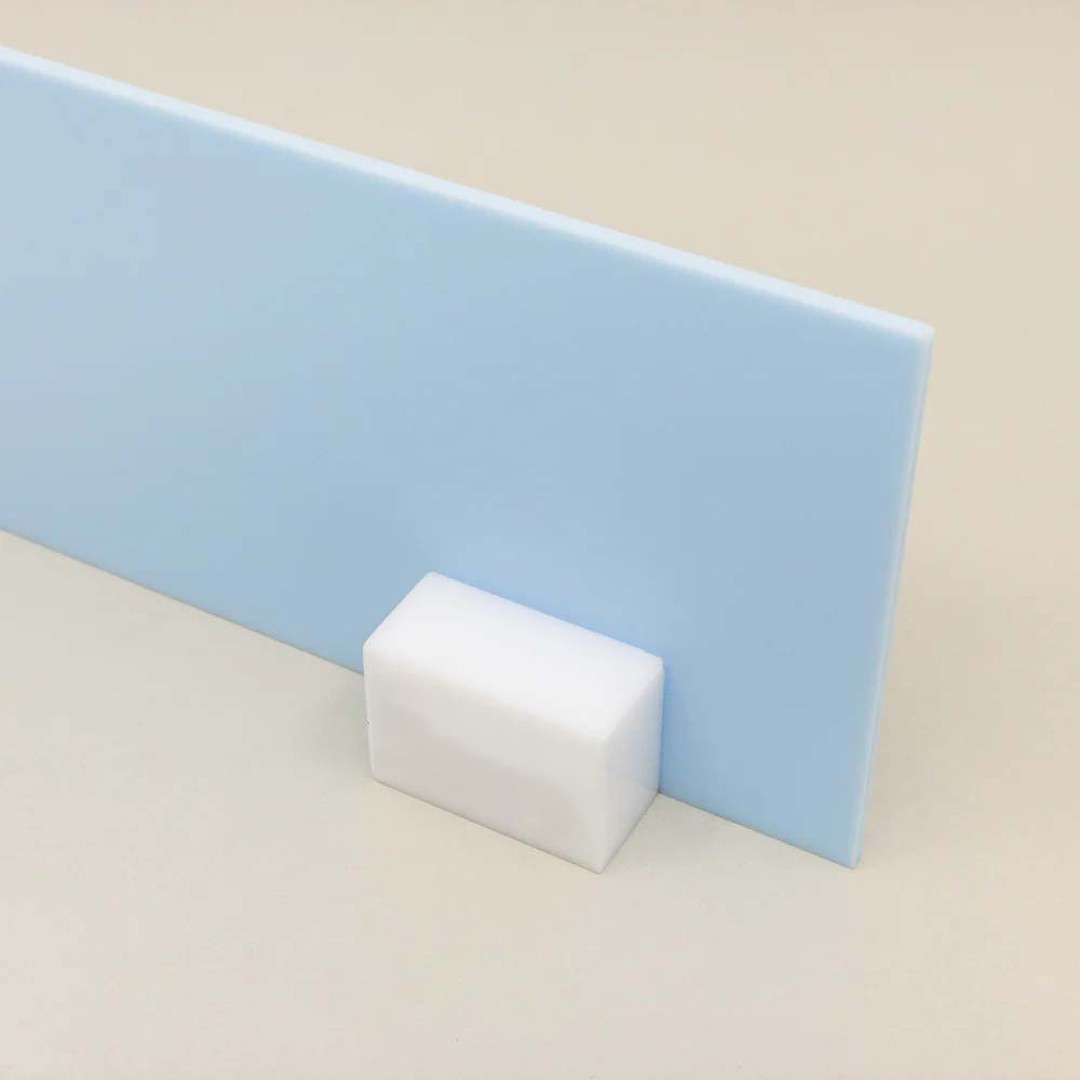

Acrylic sheets are made from polymethyl methacrylate (PMMA), a transparent thermoplastic that is known for its high optical clarity and impressive impact resistance. Acrylic is widely used as a substitute for glass due to its lighter weight, enhanced safety properties, and ease of fabrication. It can be produced in different forms such as clear, frosted, colored, and mirrored finishes, offering flexibility in design and function.

Key Properties of Acrylic Sheets:

- Transparency: Acrylic sheets are known for their superior clarity, which is comparable to glass but with better durability and lighter weight.

- Impact Resistance: Acrylic is far more resistant to impacts than glass, reducing the likelihood of breakage and improving safety.

- UV Stability: Acrylic sheets are naturally resistant to UV rays, preventing degradation and discoloration when exposed to sunlight over time.

- Yengil: Acrylic is half the weight of glass, making it easier to handle, cut, and install, especially in larger sizes.

- Customizability: Acrylic sheets can be easily cut, drilled, engraved, and shaped to meet specific project requirements, offering endless possibilities for creative applications.

Factors to Consider When Choosing Acrylic Sheets

Choosing the right acrylic sheet involves evaluating several factors, including application, thickness, material type, finish, color, and environmental conditions. Below are the key considerations to guide your decision-making process:

1. Application Requirements

Your choice of acrylic sheet should be influenced by its intended use. Different applications may require different properties from the material. For example, if you’re designing a display case, you might prioritize optical clarity, while a protective screen might require higher impact resistance.

- Belgi: For signage, especially outdoor signs, you’ll need UV-resistant acrylic sheets that maintain clarity and color over time.

- Displeylar: Acrylic used in displays and exhibitions should offer excellent optical clarity and a high level of customization for cutting and engraving.

- Mebel: Acrylic furniture, such as tables and chairs, should have the appropriate thickness for structural integrity and UV resistance for long-lasting appeal.

2. Material Type: Cast vs. Extruded Acrylic

When selecting acrylic sheets, it’s important to distinguish between cast and extruded acrylic, as each has its advantages and is suitable for different applications.

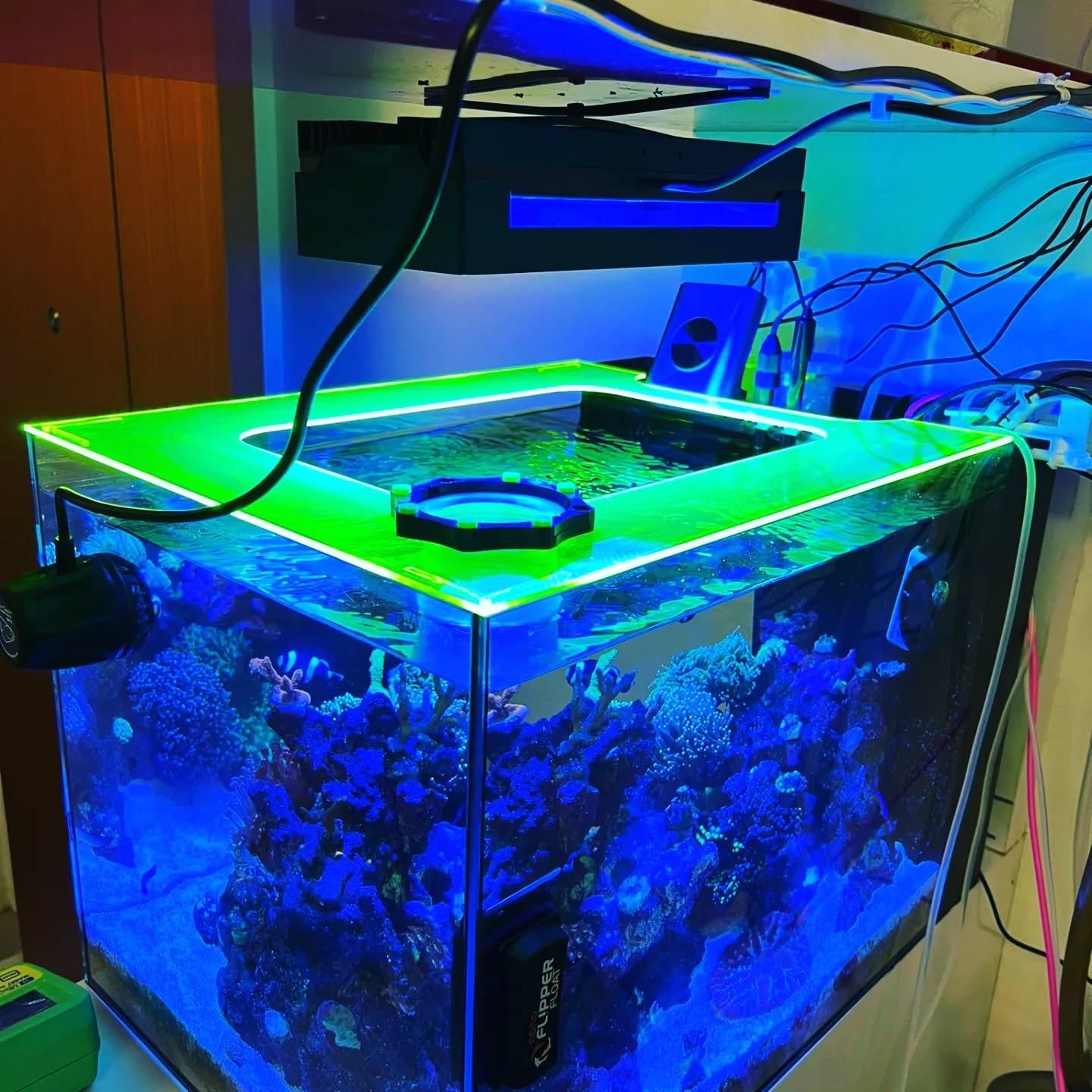

- Cast Acrylic: Cast acrylic is produced by polymerizing the monomer methyl methacrylate in a mold. This results in a sheet that is clearer, has better optical properties, and is stronger than extruded acrylic. To'qimalarining akril plitalari are ideal for applications that require a high degree of precision and clarity, such as display cases, architectural elements, and aquariums.

- Extruded Acrylic: Extruded acrylic is made by forcing the monomer through a die. While it is generally less expensive than cast acrylic, it tends to be more brittle and can be prone to cracking over time. Extruded acrylic is better suited for projects that don’t require the same level of optical clarity or strength, such as smaller signage or DIY craft projects.

3. Thickness

Acrylic sheets come in various thicknesses, and the right thickness depends on the specific requirements of your project. Thicker sheets provide better durability and impact resistance, but they can also be heavier and more difficult to handle. Conversely, thinner sheets are easier to cut and install but may not provide the same level of strength.

- Thin Acrylic Sheets (1.5 mm to 3 mm): Suitable for lightweight applications such as picture frames, small signs, and craft projects.

- Medium Acrylic Sheets (4 mm to 6 mm): Ideal for general-purpose applications, such as retail displays, signage, and light-duty protective barriers.

- Thick Acrylic Sheets (9 mm and above): Recommended for structural applications, including large aquariums, heavy-duty signage, and protective enclosures. Thicker sheets provide enhanced impact resistance and better structural integrity.

4. Color and Finish

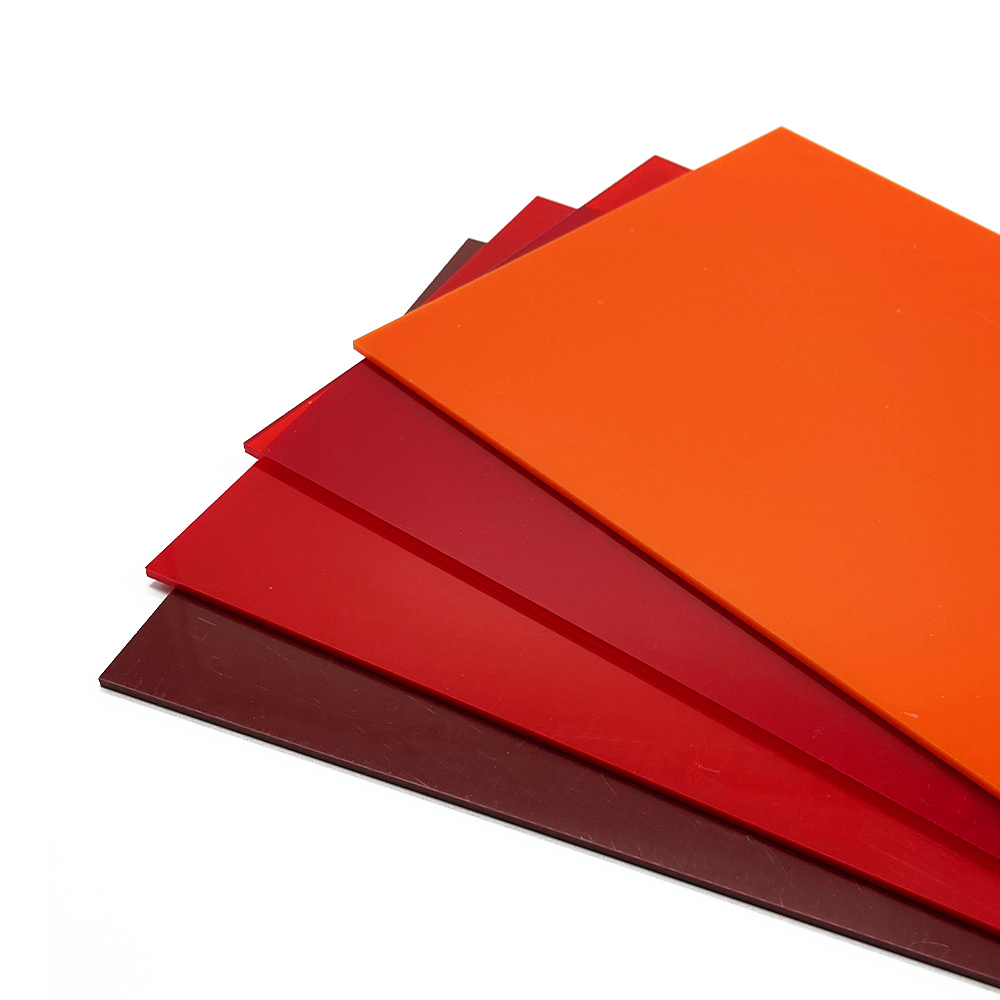

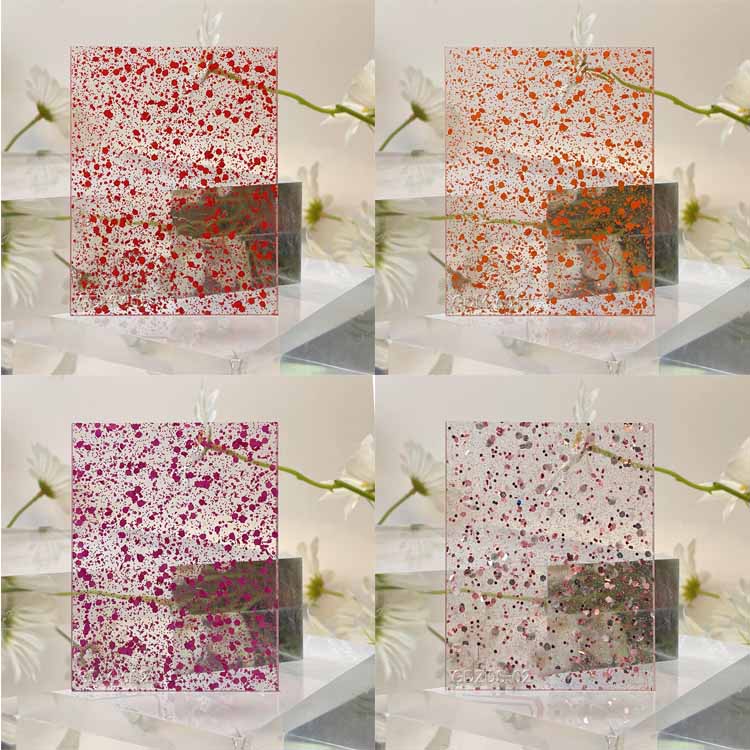

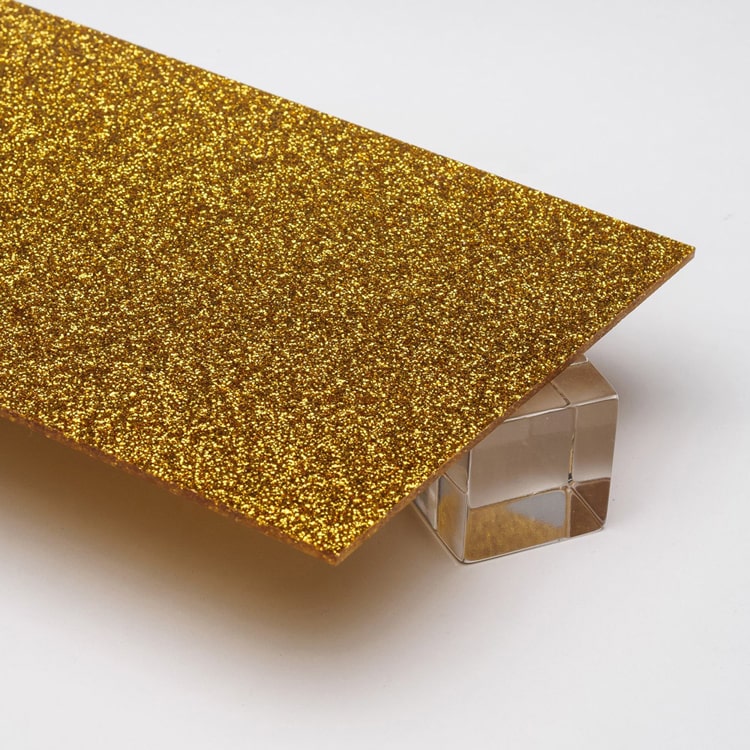

Acrylic sheets are available in a variety of colors and finishes, offering flexibility for different design needs.

- Clear Acrylic: Offers high transparency and is ideal for projects where clarity and visibility are essential.

- Colored Acrylic: Available in a range of vibrant colors, colored acrylic sheets are used for decorative elements, branding, or creating a visually striking appearance.

- Frosted Acrylic: Provides a translucent, matte finish that is perfect for creating privacy screens, light diffusers, and softer visual effects.

- Mirrored Acrylic: Offers a reflective surface, ideal for creating decorative and functional applications like mirrors or reflective signage.

- Textured Acrylic: Features a patterned surface that can reduce glare and add a unique visual element to projects.

5. UV Resistance

For outdoor applications, choosing acrylic sheets with UV resistance is essential to prevent yellowing and degradation from prolonged exposure to sunlight. UV-resistant acrylic sheets are specially formulated to withstand the effects of UV rays, ensuring that your acrylic signage or display remains clear and vibrant over time.

- UV-Resistant Acrylic: This type of acrylic is treated with a UV stabilizer to protect it from the harmful effects of UV radiation. It’s suitable for outdoor signage, displays, and protective barriers.

6. Chemical and Abrasion Resistance

Acrylic sheets offer good resistance to many chemicals, but it’s important to verify that the sheet is suitable for your specific environment. If the acrylic is exposed to harsh chemicals or cleaning agents, you’ll want to ensure that it can withstand the exposure without deteriorating.

- Abrasion-Resistant Coatings: Some acrylic sheets come with a coating that protects against scratches and general wear and tear. This feature is especially important for applications like protective barriers, where frequent contact is likely.

7. Fabrication and Ease of Processing

Acrylic sheets are easy to cut, drill, and fabricate, but it’s essential to consider the type of acrylic when determining how easily it can be processed.

- Cast Acrylic: Cast acrylic is generally preferred for applications requiring precise machining, such as turning on engine lathes or milling/drilling, due to its superior surface finish and optical properties.

- Extruded Acrylic: Extruded acrylic may require additional care when cutting or drilling to avoid cracking or splintering, especially at thinner thicknesses.

Choosing the Right Acrylic Sheet for Your Project

To make an informed decision about which acrylic sheet is right for your project, consider the following guidelines:

- Belgi: If you’re designing signage, especially for outdoor use, opt for UV-resistant, clear acrylic sheets with medium thickness (4 mm to 6 mm). For indoor displays, consider frosted or colored acrylic for added aesthetic appeal.

- Protective Barriers: For protective barriers or shields, choose thick cast acrylic (9 mm or higher) with impact resistance and UV protection for longevity.

- Mebel: If you’re creating acrylic furniture or shelving, opt for medium to thick acrylic sheets with UV resistance to prevent yellowing and ensure structural integrity.

- Crafts and DIY Projects: Thin acrylic sheets (1.5 mm to 3 mm) are ideal for arts and crafts, small projects, and signs. Consider extruded acrylic for simpler projects, as it is easier to work with and more affordable.

Xulosa

Selecting the right acrylic sheet involves understanding your specific needs, including the application, thickness, finish, color, and durability requirements. By considering these factors, you can ensure that the chosen acrylic sheet aligns with both functional needs and aesthetic preferences, thereby enhancing the overall success and longevity of your project.

From impact resistance to UV protection, color choices to fabrication ease, every decision contributes to the quality and aesthetic of your acrylic projects. Understanding these aspects will help you select the best acrylic sheet that meets both your design and practical requirements.