Table of Contents

Acrylic is widely used in the construction and decoration industries due to its excellent transparency, weather resistance, and ease of processing. It is commonly used in a variety of applications such as windows, display racks, and bathroom accessories. Understanding the cost of acrylic per square meter is crucial for budget planning and project management. This article will explore the factors that contribute to the cost of acrylic, analyze common price ranges in the market, and discuss how to optimize procurement strategies to control expenses.

Average Cost of Acrylic Per Square Meter

Based on current market trends, the average cost of acrylic is approximately £30 per square meter. However, the price may vary depending on factors such as the supplier, quantity purchased, and material thickness. For instance, high-quality acrylic materials, especially those with customized sizes or special colors, may cost more than standard acrylic sheets. Thin acrylic sheets are generally cheaper, while thicker acrylic sheets typically incur higher costs.

Here are some common price ranges:

- Standard transparent acrylic: Prices range from £20 to £35 per square meter.

- High-quality acrylic (with special surface treatment): Prices may reach £50 per square meter or more.

- Custom sizes and colors: Prices may increase depending on design and customization requirements.

These figures are derived from a comparison of quotes provided by various online markets and suppliers. Actual prices may vary depending on bulk purchasing, long-term partnership agreements, and other commercial negotiation factors.

Factors Affecting the Cost of Acrylic

When considering the cost of acrylic, several key factors directly impact the final price. Understanding these factors will help procurement professionals optimize their budgets and make more cost-effective purchasing decisions.

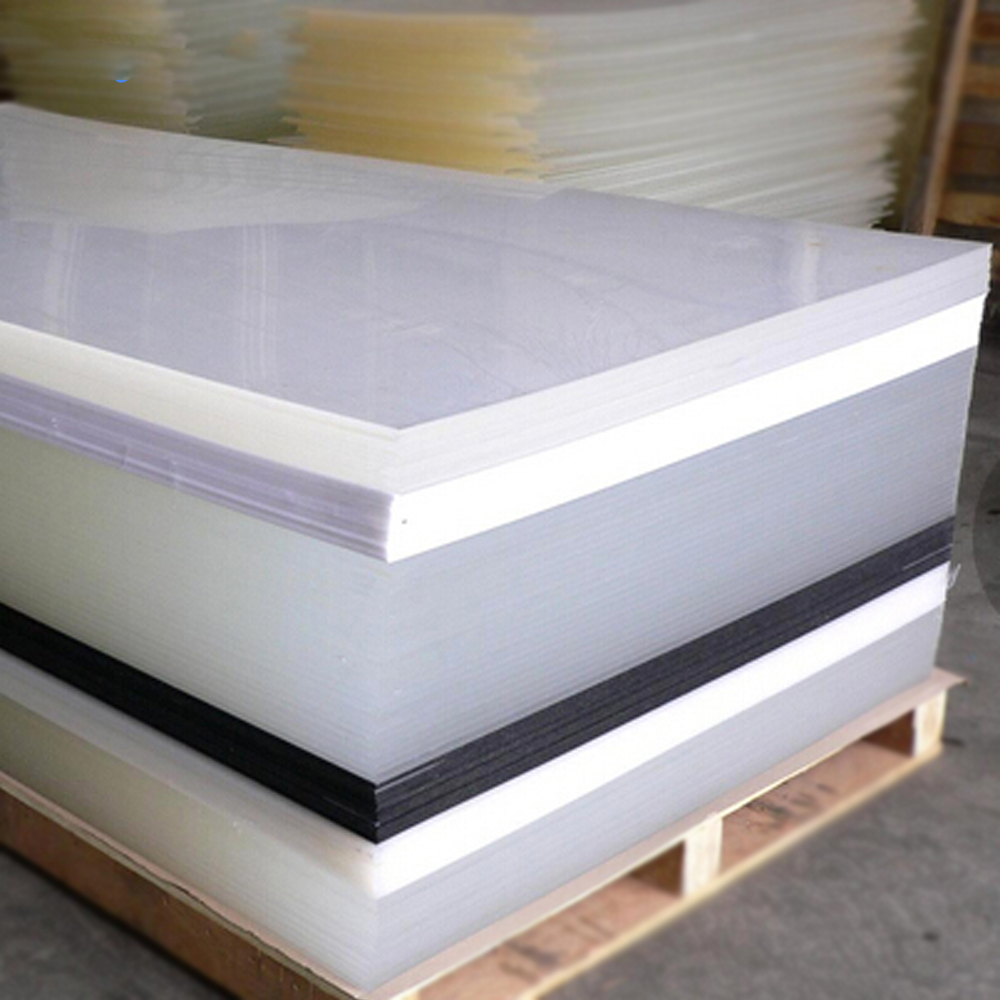

1. Material Thickness

The thickness of acrylic sheets is an important factor in determining their price. Thicker acrylic sheets, while stronger and more durable, typically cost more due to the increased use of raw materials. For example, a 5mm thick acrylic sheet is more expensive than a 3mm sheet and is typically used in applications that require higher strength and durability, such as large display racks or exterior architectural decorations.

2. Quantity Purchased

The unit price of acrylic generally decreases as the quantity purchased increases. Many suppliers offer bulk discounts, which can help reduce costs when purchasing large quantities. For large-scale projects or companies with ongoing needs, bulk purchasing is an effective way to lower overall material costs.

3. Supplier and Brand

The price of acrylic is not only related to its quality and specifications but also to the pricing strategies of different suppliers. Acrylic materials from well-known brands may be priced higher due to brand recognition, production processes, or market positioning. For example, premium brands of acrylic materials may cost more, but they often guarantee higher quality standards and better after-sales service.

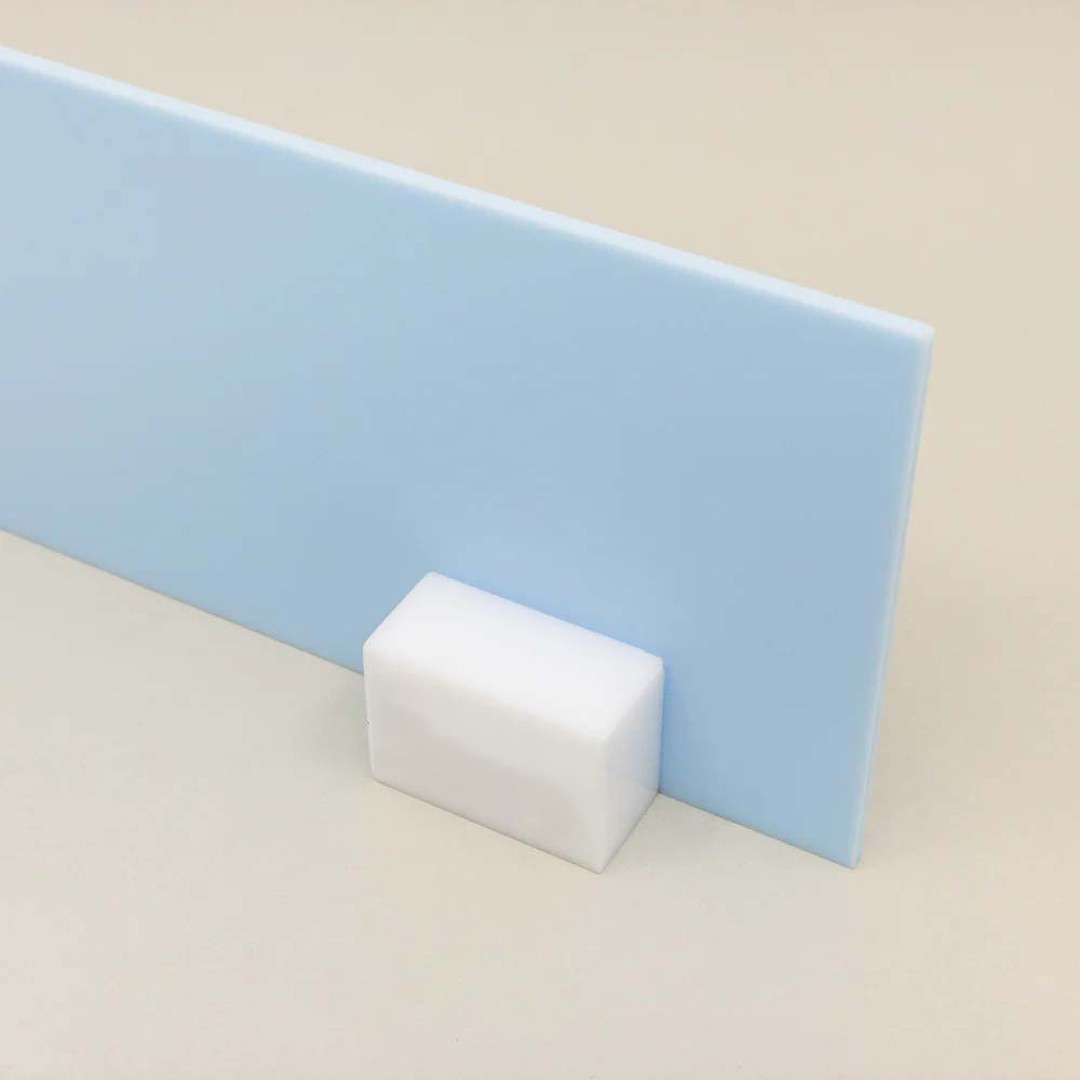

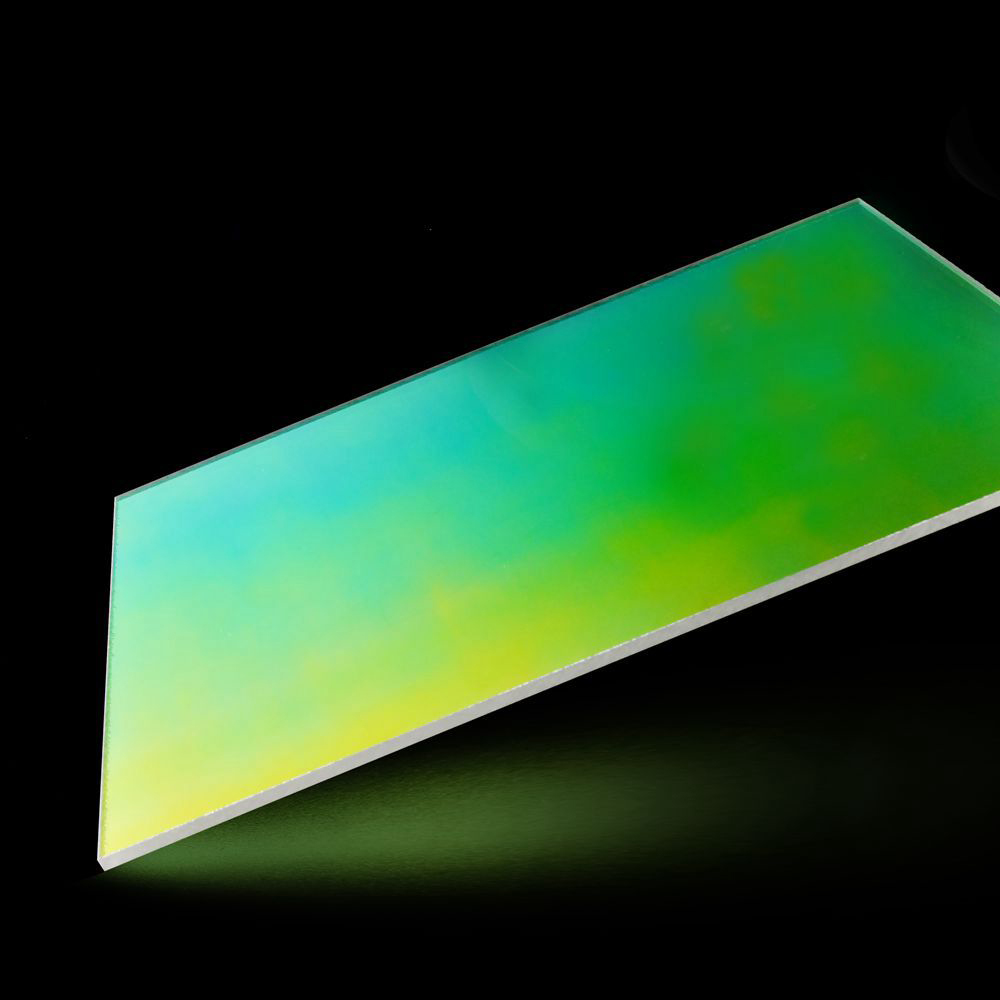

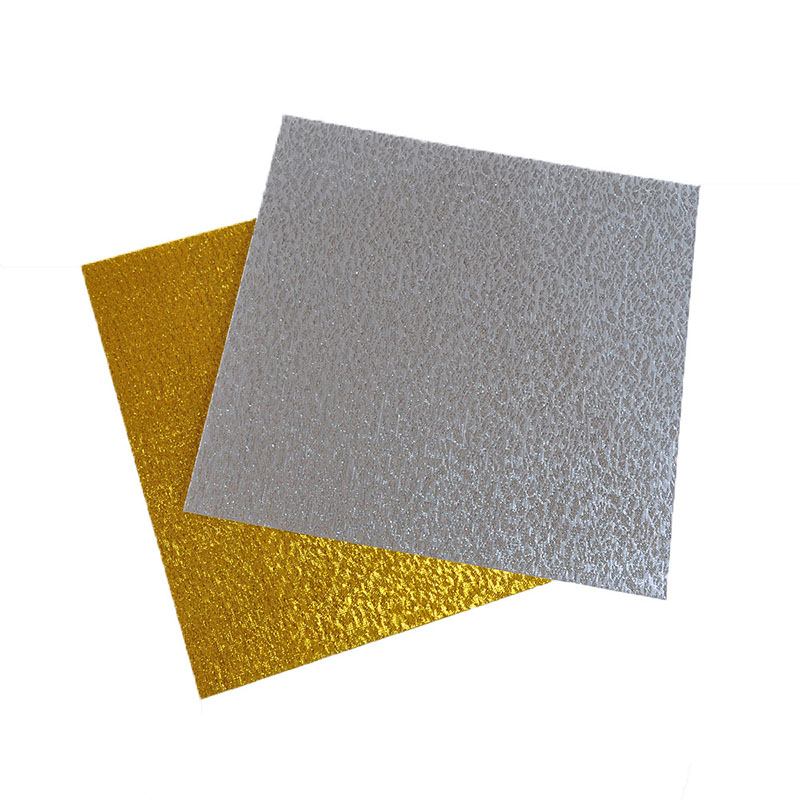

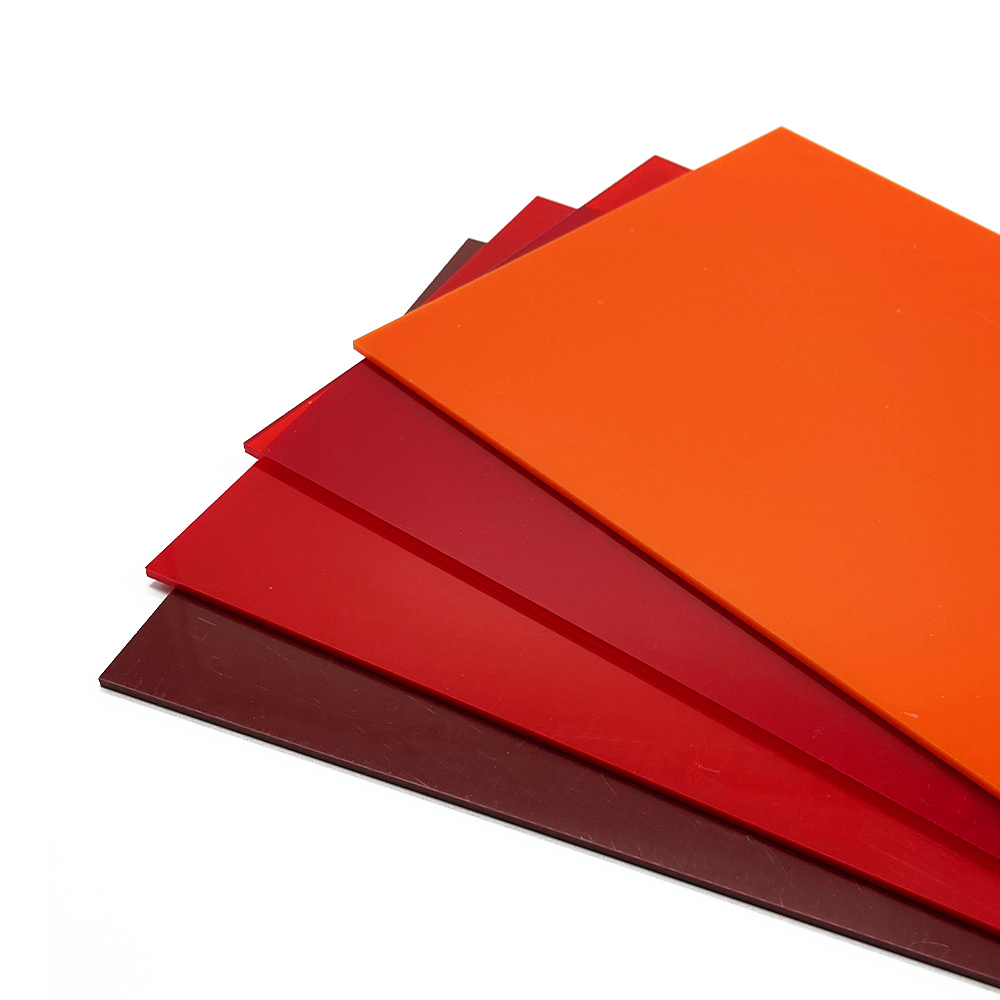

4. Color and Surface Treatment

The color and surface treatment of acrylic sheets also affect the price. Transparent acrylic sheets are typically the most common and cost-effective, but if you need custom colors, frosted surfaces, or UV-resistant coatings, the production process becomes more complex, which results in higher costs. Choosing standard transparent sheets instead of customized designs is an effective way to control your budget.

5. Transportation and Installation Costs

While the material cost is a significant factor, transportation and installation costs can also greatly impact the overall budget. Acrylic sheets that are large or heavy can incur higher transportation fees, especially if you need to ship them over long distances. Additionally, installation costs, particularly for customized designs or special treatments, should be considered as part of the total project cost.

Applications of Acrylic

Acrylic is widely used across multiple industries due to its unique physical properties and versatility. Below are some common application scenarios where acrylic’s transparency and durability are of utmost importance.

1. Windows and Doors

Acrylic is used as a replacement for glass in windows and doors in the construction industry. It not only offers excellent transparency but is also lighter and more impact-resistant than traditional glass, providing better sound insulation. Acrylic windows and doors are an ideal choice for projects that require higher security or lighter materials.

2. Display Racks and Signage

Due to acrylic’s exceptional transparency, it is commonly used in display racks and signage. Whether for retail store display cabinets or corporate signage, acrylic provides a clear, sleek visual effect and is easy to cut and process, allowing for customized display solutions.

3. Bathroom Accessories

Acrylic is also widely used in bathroom accessories such as shower screens, bathtubs, and bathroom dividers. Its water-resistant and high-temperature-resistant properties make it an excellent choice for use in moist environments. Furthermore, the smooth surface of acrylic reduces water retention and the growth of bacteria, offering better hygiene.

4. Lighting Covers and Fixtures

Acrylic is ideal for making lighting covers and lightbulb casings due to its excellent light transmission properties. Whether used for indoor or outdoor lighting, acrylic enhances the lighting fixtures’ light efficiency and durability.

How to Reduce Acrylic Procurement Costs

There are several ways to lower the procurement costs of acrylic. By using some strategies and techniques, you can effectively reduce the overall spending on materials for your projects.

1. Bulk Purchasing

Bulk purchasing can help you obtain discounts from suppliers. This is particularly important for large projects or long-term partnerships. Many suppliers offer bulk order discounts, and prices can be fixed through negotiations for long-term agreements.

2. Compare Quotes from Different Suppliers

There are multiple suppliers offering acrylic materials in the market, so comparing quotes and services is an effective way to save costs. By evaluating suppliers’ reputation, delivery times, transportation fees, and other factors, you can select the supplier that provides the best value for your money.

3. Choose Standard Specifications and Common Types

Custom sizes and special requirements for acrylic sheets generally come at a higher cost. Choosing standard thicknesses and common types of acrylic materials is another effective strategy to reduce costs. If your project doesn’t involve special aesthetics or performance needs, opting for standardized acrylic sheets can help save unnecessary expenses.

Conclusion

Acrylic is a high-performance, durable, and transparent material widely used in construction, decoration, and lighting industries. Understanding its cost per square meter, as well as the factors influencing its price, will help designers and procurement professionals make more informed decisions. In terms of budget control, selecting the right thickness, specifications, and suppliers, purchasing in bulk, and opting for standard designs are all effective ways to optimize procurement costs.

As market competition intensifies and the range of materials continues to diversify, adopting rational procurement strategies will help you minimize project costs while maintaining quality. Acrylic will continue to be a crucial material in the coming years, and understanding its cost structure and how to manage expenses is essential for any project involving its use.