Table of Contents

In today’s era of diverse materials, acrylic sheets have become a popular choice in construction, displays, and DIY projects due to their exceptional optical clarity, weather resistance, and versatility. However, evaluating the cost of an acrylic sheet involves more than just a surface glance. Factors such as thickness, size, manufacturing processes, and additional surface treatments all play a crucial role in determining the final price. This article delves into the key variables influencing acrylic sheet pricing—from raw material fluctuations and production techniques to standard sizes versus custom cutting—helping you assess the true value of your investment. Whether you are a professional in the industry or an enthusiastic DIYer, this guide will reveal the economic principles behind acrylic sheet costs and enable you to make informed decisions.

1. Understanding Acrylic Sheets

1.1 What Are Acrylic Sheets?

Acrylic sheets—often referred to as Plexiglass or Lucite—are produced from polymethyl methacrylate (PMMA), a transparent thermoplastic prized for its lightweight properties, high optical clarity, and excellent weather resistance. These characteristics make acrylic a favorable alternative to glass in many applications.

Cast Acrylic

Cast acrylic is made by pouring liquid acrylic resin into molds and allowing it to cure. This process results in sheets with superior optical clarity, uniform thickness, and outstanding weatherability. These advantages, however, come at a higher price due to the more labor-intensive production process.

Extruded Acrylic

Extruded acrylic is produced via a continuous extrusion process, making it more cost-effective. Although it may exhibit slight variations in thickness and surface finish compared to cast acrylic, extruded acrylic is ideal for budget-conscious projects.

1.2 Applications and Market Demand

Acrylic sheets are extensively used in architectural glazing, retail signage, display cases, and various DIY projects. Their high performance and versatility drive strong market demand, which in turn influences pricing based on quality, thickness, and customization requirements.

2. Factors Influencing Acrylic Sheet Pricing

2.1 Raw Material Costs

The primary raw material for acrylic sheets is the methyl methacrylate (MMA) monomer. The quality and market price of MMA directly affect the final product. Premium-grade MMA produces clearer and more durable sheets but comes at a higher cost. Global fluctuations in oil prices and raw material availability further influence production expenses.

2.2 Manufacturing Processes and Technology

The production method significantly impacts cost. Cast acrylic, with its labor-intensive curing process, generally commands a higher price compared to extruded acrylic, which benefits from continuous production and lower costs. Additionally, energy consumption and sophisticated equipment used in production contribute to overall expenses.

2.3 Sheet Dimensions and Specifications

Thickness and Size

Thickness is a primary cost determinant. For example, a standard 4′ x 8′ sheet of 1/8″ (3mm) acrylic typically costs around $100, while thicker sheets—such as 1/4″ or 1/2″—incur significantly higher costs due to increased material usage and more complex processing.

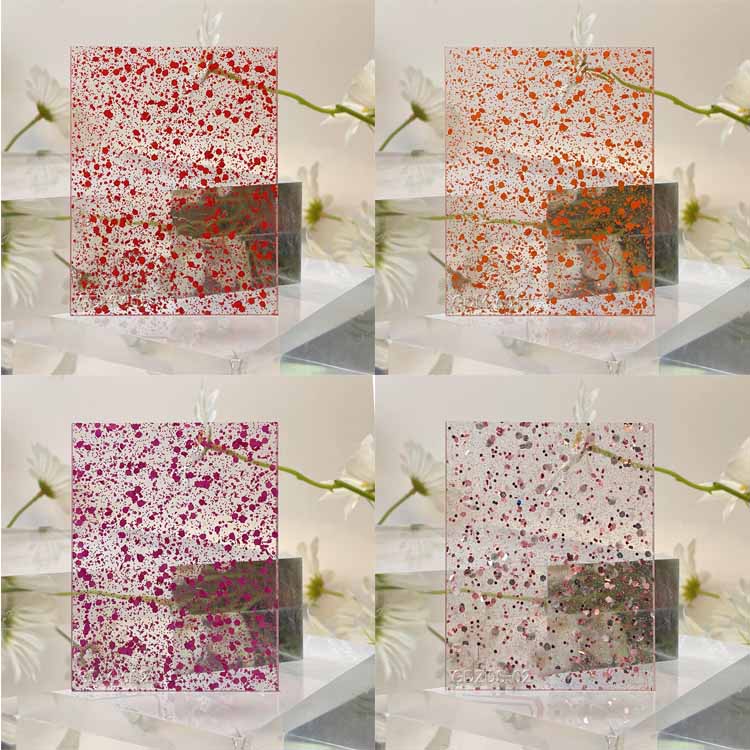

Surface Treatments and Finishes

Additional features like frosted, mirrored, or colored finishes require extra processing steps, further elevating the price relative to standard clear acrylic sheets.

2.4 Order Quantity and Volume Discounts

Purchasing in bulk often results in a lower per-unit cost because of economies of scale. In contrast, small or custom orders may incur higher per-unit costs due to setup fees and reduced production efficiencies.

2.5 Value-Added Features

Specialized features such as UV stabilization, impact modification, or custom cutting add extra value—and cost—to the final product. These enhancements are essential for specific applications but increase the overall price of the acrylic sheet.

3. Market Trends and Supply Chain Influences

3.1 Global Supply and Demand Dynamics

Global market conditions, including increased demand in emerging markets and supply chain disruptions, can lead to temporary price surges. Trade policies and international raw material availability also play significant roles in pricing fluctuations.

3.2 Economic Factors

Inflation, exchange rate fluctuations, and regional economic conditions affect production costs, which are then reflected in the price of acrylic sheets. These economic variables must be considered when planning large projects.

4. Comparing Acrylic Costs with Alternative Materials

4.1 Glass

Glass is a traditional alternative to acrylic; however, a 4′ x 8′ sheet of 1/8″ thick glass can cost around $200—roughly double the cost of acrylic. Additionally, glass is heavier and more fragile, which increases both shipping and installation costs.

4.2 Polycarbonate

Polycarbonate offers similar transparency and is comparably priced for standard sizes. However, it may lack the scratch resistance and long-term clarity of acrylic, particularly under prolonged UV exposure.

4.3 PVC Foam Board

PVC foam board is a more economical option, often priced around $50 per 4′ x 8′ sheet. Despite its affordability, PVC foam board does not match acrylic in durability, aesthetics, or long-term performance.

5. Calculating the Cost of One Acrylic Sheet

5.1 Determine the Required Area

For a standard 4′ x 8′ sheet, calculate the area by multiplying the length by the width (4′ × 8′ = 32 square feet).

5.2 Select the Desired Specifications

Choose the required thickness, type (cast or extruded), and finish based on your project’s needs. Each specification has an associated cost per square foot.

5.3 Compute the Material Cost

Multiply the area by the cost per square foot. For example, if a 1/8″ sheet costs $3.50 per square foot, the material cost is 32 × $3.50 = $112.

5.4 Factor in Additional Costs

Include any extra fees for shipping, custom cutting, and taxes to arrive at the final price of the acrylic sheet.

6. Evaluating Long-Term Value and Cost-Effectiveness

6.1 Durability and Maintenance

Acrylic’s durability, lightweight nature, and resistance to weathering translate into long-term savings. Unlike glass, acrylic is less prone to shattering, reducing both installation and replacement costs over time.

6.2 Versatility and Application Efficiency

The ease of machining and fabrication makes acrylic suitable for a wide range of applications, allowing it to serve multiple functions within a single project and ultimately lowering overall material costs.

7. Conclusion

Determining the cost of one acrylic sheet requires a comprehensive understanding of various factors—from raw material quality and manufacturing methods to dimensions and value-added features. While a standard 4′ x 8′ 1/8″ clear acrylic sheet typically costs between $90 and $120, final prices vary based on specific requirements and market conditions.

When compared with alternatives such as glass, polycarbonate, or PVC foam board, acrylic’s superior optical clarity, durability, and versatility often justify its higher price. By considering both immediate purchase costs and long-term benefits, you can make an informed decision that maximizes your investment.

Final Thoughts

Understanding the various factors that contribute to the cost of an acrylic sheet empowers you to make informed procurement decisions. By analyzing raw material quality, manufacturing techniques, dimensions, and additional features, you can accurately determine the true cost and long-term value of acrylic sheets for your projects.

Invest wisely by leveraging bulk discounts and standard sizes to maximize cost-effectiveness, ensuring that your investment in acrylic meets your performance needs while delivering exceptional value over time.

Frequently Asked Questions (FAQs)

FAQ 1: How do I accurately calculate the cost of one acrylic sheet for my project?

Begin by measuring the required area and determining the cost per square foot based on the sheet’s thickness and finish. Multiply these figures and add any additional fees such as cutting, shipping, and taxes.

FAQ 2: What are the key factors that affect acrylic sheet pricing?

Key factors include the quality of the raw material (MMA), the manufacturing process (cast vs. extruded), sheet thickness and size, surface treatments, and market dynamics like bulk order discounts.

FAQ 3: Is investing in a higher-priced acrylic sheet worth it compared to alternatives like glass or PVC foam board?

Yes. Although acrylic sheets may have a higher upfront cost, their superior durability, optical clarity, lightweight design, and lower maintenance requirements often result in long-term savings compared to alternatives.