Inhaltsverzeichnis

Acrylic sheets are widely used across various industries, from construction and decoration to signage and display purposes. Their exceptional clarity, durability, and versatility make them an ideal material for numerous applications. Whether you are a contractor, designer, or business owner, understanding how to accurately calculate the price of acrylic sheets is crucial for budgeting and procurement. This article will delve into the key factors that influence the cost of acrylic sheets, offer a step-by-step guide on how to calculate the price, and provide insights into how to optimize procurement strategies to achieve cost savings.

Key Factors Affecting the Price of Acrylic Sheets

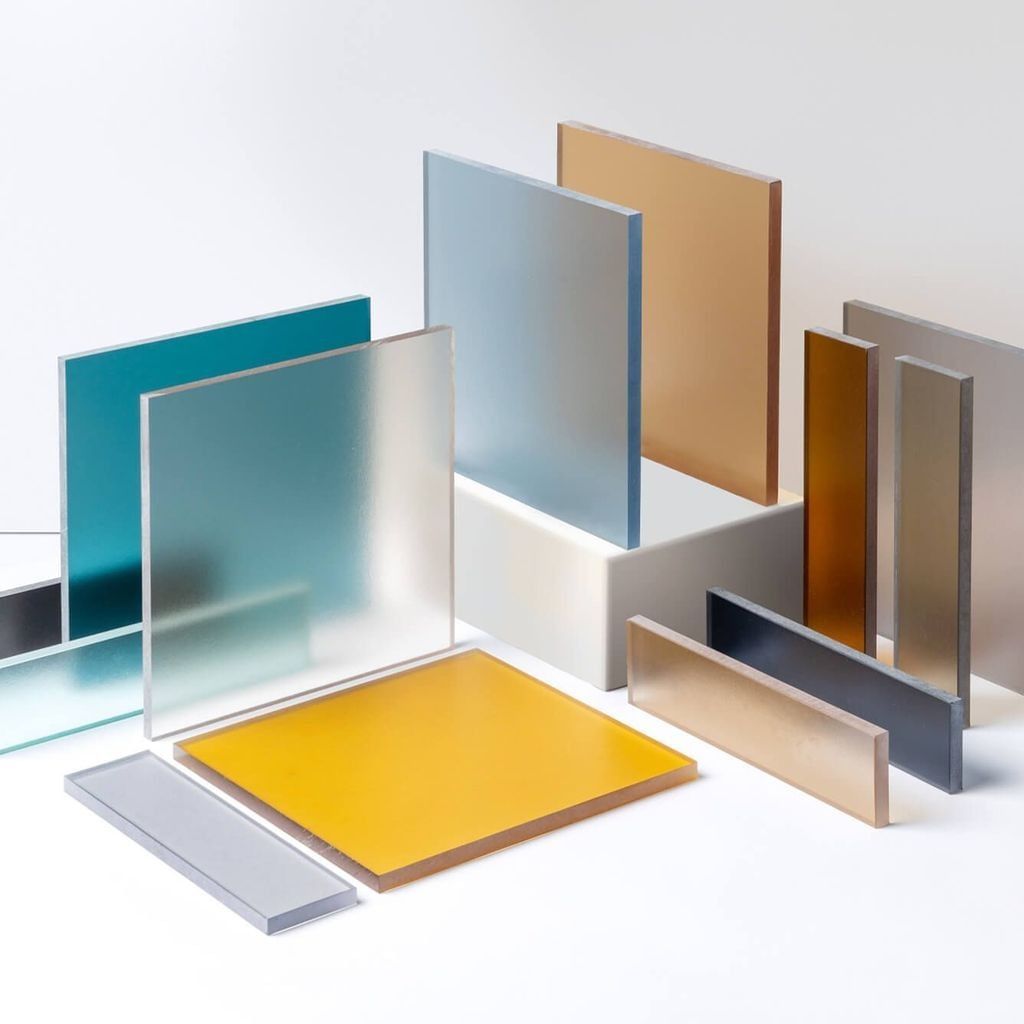

The cost of acrylic sheets can vary widely depending on several factors. Understanding these elements will help you estimate the price more accurately and make informed purchasing decisions.

1. Materialqualität

The quality of the acrylic resin used to manufacture the sheets is one of the primary factors affecting the price. High-quality acrylic sheets are produced with superior-grade resins, which offer better clarity, weather resistance, and longevity. These premium materials often result in a higher price point due to their durability and enhanced performance in demanding applications.

Lower-quality acrylic sheets, on the other hand, might contain impurities or cheaper additives that can compromise their transparency and overall performance. These sheets are typically less expensive but may not be suitable for applications requiring high optical clarity or durability, such as display cases or glass replacements.

2. Sheet Thickness

The thickness of an acrylic sheet significantly impacts its price. Thicker sheets require more raw materials and involve more complex production processes, which increases manufacturing costs. For instance, a 3mm thick acrylic sheet will be more affordable compared to a 5mm or 10mm thick sheet. Thicker acrylic sheets are often used for heavy-duty applications, such as large signage or structural panels, where additional strength and impact resistance are required.

For lighter applications, such as window glazing or decorative pieces, thinner sheets may suffice and cost considerably less. Therefore, understanding the thickness requirements of your project is key to determining how much to budget for acrylic materials.

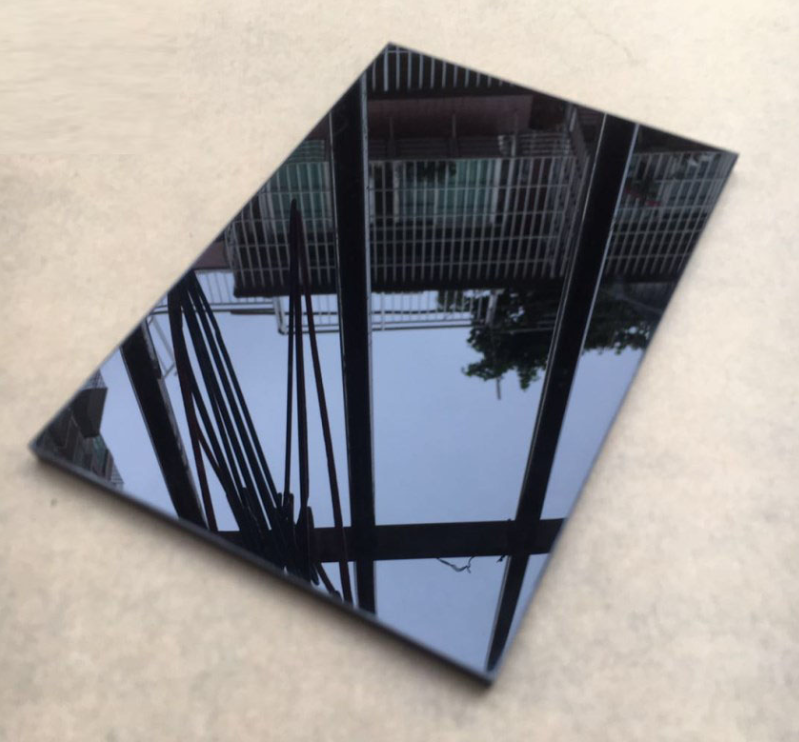

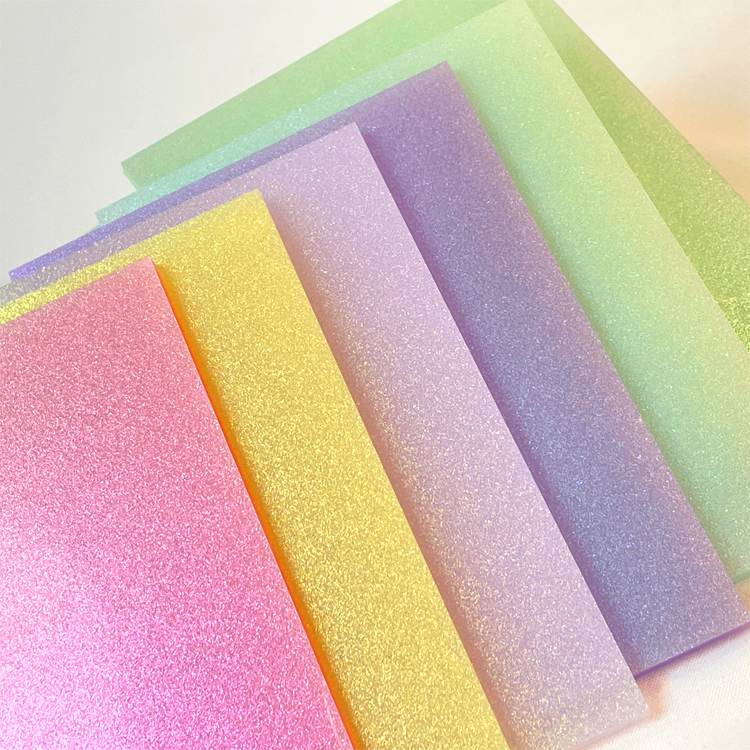

3. Surface Treatment and Color

The type of surface treatment and the color of the acrylic sheet can also affect its cost. Standard transparent acrylic sheets are typically the least expensive option. However, acrylic sheets with specialized surface treatments, such as frosted, mirrored, or UV-resistant coatings, often come at a premium price due to the additional processing involved.

Custom colors, patterns, or textured finishes will further increase the price. Custom-colored acrylic sheets require additional production steps, including the use of dyes or pigments, which can raise manufacturing costs. If your project requires specific aesthetics, these additional features should be factored into the pricing.

4. Size and Customization

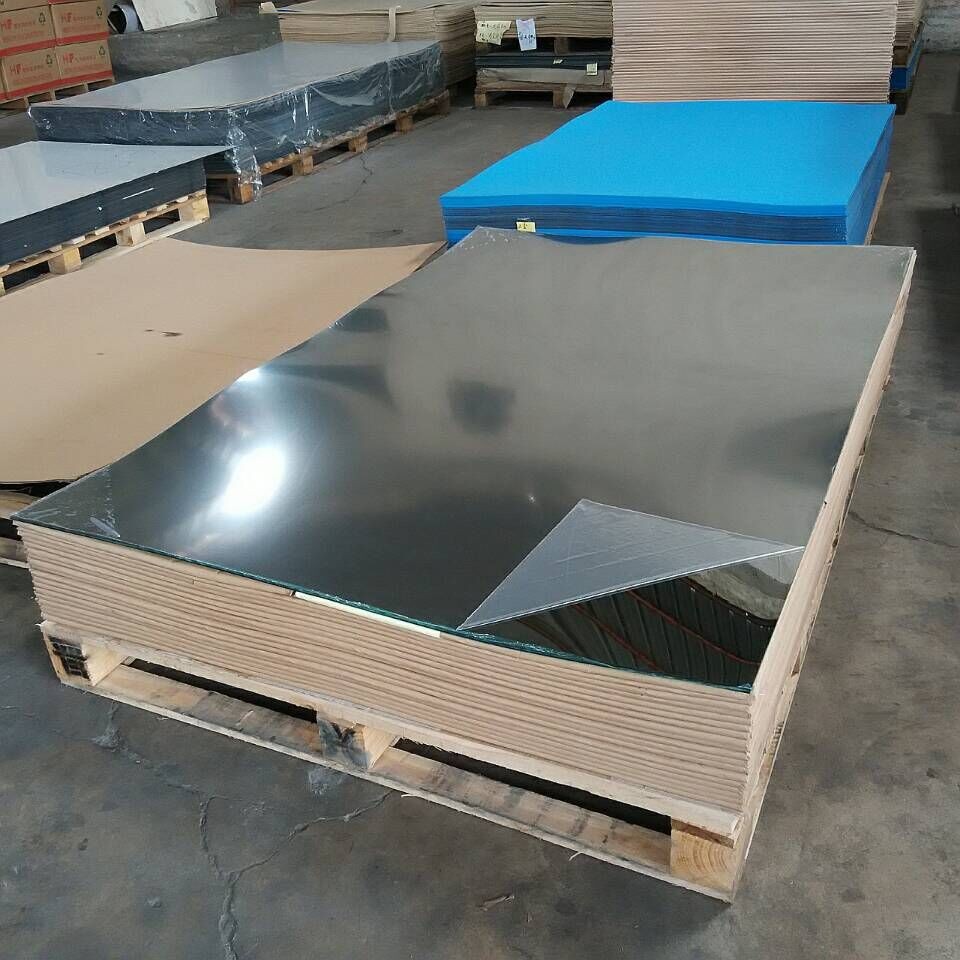

Standard-sized acrylic sheets (e.g., 4×8 feet or 2×2 meters) are generally more cost-effective compared to custom-sized sheets. Customization may include requests for non-standard shapes, cuts, or sizes, which often require special handling and equipment to produce, increasing both labor and material costs.

When requesting custom-cut acrylic sheets, it is important to provide accurate measurements and specifications to avoid errors that could lead to waste or additional expenses. Additionally, cutting or shaping acrylic sheets can require advanced machinery, which could further increase the price depending on the complexity of the required cuts.

5. Brand and Supplier

The brand and supplier of acrylic sheets play a significant role in pricing. Well-known and reputable brands often command higher prices due to their established product quality and the reliability of their supply chains. These brands are more likely to offer warranties, consistent product quality, and robust customer support, which justifies the premium.

However, choosing lesser-known suppliers may help reduce costs, but you should carefully assess the quality and reputation of these suppliers to ensure that the acrylic sheets meet your project’s requirements. Additionally, working with a supplier who offers bulk discounts, free shipping, or other cost-saving benefits can help further reduce expenses.

How to Calculate the Price of an Acrylic Sheet

Once you understand the factors that influence the price of acrylic sheets, you can proceed with calculating the cost based on your specific project needs. Below is a step-by-step guide on how to calculate the price of an acrylic sheet.

1. Determine the Required Sheet Area

The first step in calculating the price is to determine the total area of acrylic you need. To do this, measure the length and width of the area where the acrylic sheet will be installed. Multiply these two dimensions to calculate the area in square meters or square feet, depending on the unit of measurement.

Example: If you need a piece of acrylic that is 2 meters long and 1 meter wide, the total area will be:

- Area = Length × Width = 2m × 1m = 2 square meters

2. Select the Acrylic Sheet Specifications

Next, choose the specifications for the acrylic sheet you wish to purchase, including the thickness, color, surface treatment, and any additional features like UV protection or scratch resistance. These factors will directly affect the price per square meter.

3. Obtain Supplier Quotes

Contact multiple suppliers to get quotes for the specific acrylic sheet you need. When requesting a quote, be sure to provide all the necessary details, including the size, thickness, and surface treatment of the acrylic sheet. Additionally, inquire about any additional costs such as shipping fees, cutting fees, and taxes.

It is essential to compare quotes from various suppliers to ensure you are getting the best deal for your budget while maintaining the required product quality.

4. Calculate the Material Cost

Once you have the price per square meter or square foot from your supplier, multiply it by the total area of acrylic you need. This will give you the material cost for your project.

Example: If the quote for a 3mm thick acrylic sheet is £50 per square meter and you need 2 square meters, the cost will be:

- Material Cost = £50 × 2 = £100

5. Add Additional Costs

In addition to the material cost, there may be other costs to consider, such as shipping, handling, and custom cutting fees. Be sure to factor in these additional expenses to get an accurate total cost for the acrylic sheets.

Example: If the shipping cost is £20, and the cutting fee is £10, the total cost for the acrylic sheets will be:

- Total Cost = £100 (material) + £20 (shipping) + £10 (cutting) = £130

Practical Tips for Reducing Acrylic Sheet Costs

While acrylic sheets can be relatively expensive, there are several ways to optimize costs without sacrificing quality or functionality. Below are some practical tips to help you reduce your acrylic sheet expenses:

1. Purchase in Bulk

If you have a large-scale project or multiple projects requiring acrylic sheets, purchasing in bulk can significantly reduce the price per unit. Many suppliers offer bulk discounts, which can help lower your overall cost. Additionally, you may be able to negotiate better prices for long-term contracts or repeat orders.

2. Choose Standard Sizes

Opting for standard-sized acrylic sheets, such as 4×8 feet or 2×2 meters, can save money compared to custom-sized sheets. Standard sizes are more readily available and do not require special processing, making them a cost-effective option for many applications.

3. Compare Different Suppliers

Take the time to compare quotes from multiple suppliers, both online and offline. Prices can vary significantly between suppliers, so it is important to shop around for the best deal. Look for suppliers that offer additional benefits, such as free shipping, volume discounts, or loyalty programs.

4. Limit Customization

Customizing acrylic sheets, whether through specific colors, shapes, or surface treatments, can significantly increase costs. If your project does not require specialized features, sticking to basic transparent sheets or avoiding custom cuts can help reduce expenses.

Abschluss

Calculating the price of acrylic sheets involves considering a variety of factors, including material quality, sheet thickness, surface treatment, size, and the supplier you choose. By carefully analyzing these elements and following the steps outlined above, you can estimate the cost of acrylic sheets for your project accurately and effectively.

To optimize your budget, consider purchasing in bulk, comparing quotes from multiple suppliers, and choosing standard sizes to avoid unnecessary expenses. While acrylic can be an expensive material, proper planning and strategic procurement can help you manage costs without compromising on quality or performance.