جدول المحتويات

Acrylic sheet glass, often called Plexiglass, is a highly adaptable material used in countless industries and applications. Its unique combination of strength, clarity, and flexibility has made it an indispensable material for modern manufacturing, construction, and design. In this guide, we’ll explore the origins, properties, applications, and benefits of acrylic sheet glass in detail, along with frequently asked questions and advanced features that showcase its incredible potential.

The History of Acrylic Sheet Glass

The journey of acrylic began in 1928 when scientists first synthesized polymethyl methacrylate (PMMA). It became commercially available in 1933, thanks to the efforts of the Rohm and Haas Company. Acrylic gained prominence during World War II when it was used for constructing airplane windows, canopies, and gun turrets. Its lightweight nature and excellent optical clarity made it ideal for wartime applications.

After the war, acrylic sheet glass transitioned into civilian life, finding applications in industries such as construction, automotive, retail, and even art. Today, it remains one of the most versatile materials available, offering a variety of finishes, colors, and thicknesses to suit any project.

Unique Properties of Acrylic Sheet Glass

Acrylic sheet glass boasts a range of properties that distinguish it from traditional materials like glass and polycarbonate. Below are its most notable features:

1. Optical Excellence

Acrylic allows up to 92% of light to pass through, making it an excellent choice for applications requiring transparency. Unlike glass, acrylic does not yellow over time, even when exposed to prolonged sunlight.

2. Impact Resistance

Acrylic is approximately 10 times more impact-resistant than glass, making it a safer option in environments where breakage could pose a risk. When it does break, it fractures into blunt, dull pieces rather than sharp shards.

3. Lightweight

Acrylic weighs about half as much as glass, reducing the logistical challenges of handling, transport, and installation.

4. UV and Weather Resistance

Acrylic’s innate resistance to ultraviolet light and weathering makes it a popular choice for outdoor applications like signage, skylights, and greenhouse panels.

5. Thermal Insulation

Acrylic offers better thermal insulation than traditional glass, helping to improve energy efficiency in buildings and greenhouses.

6. Chemical Stability

Acrylic is resistant to a wide range of chemicals, including many cleaning agents, acids, and bases, making it a durable option for industrial environments.

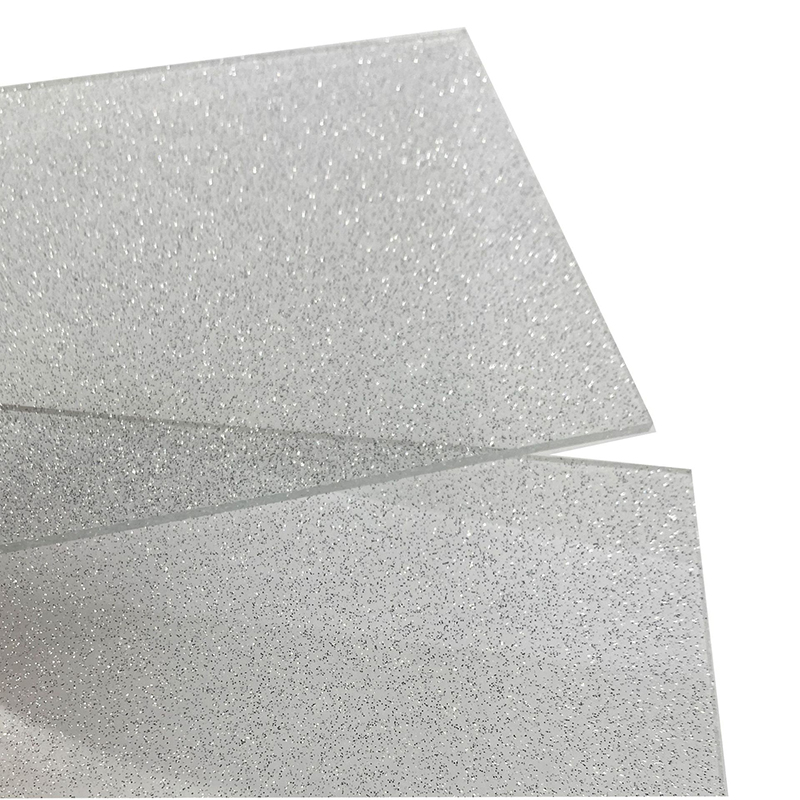

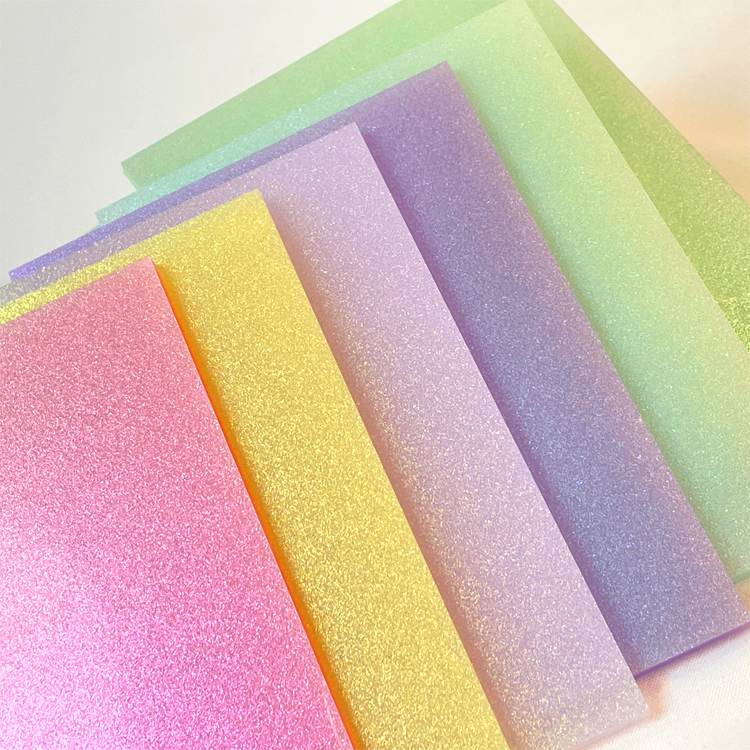

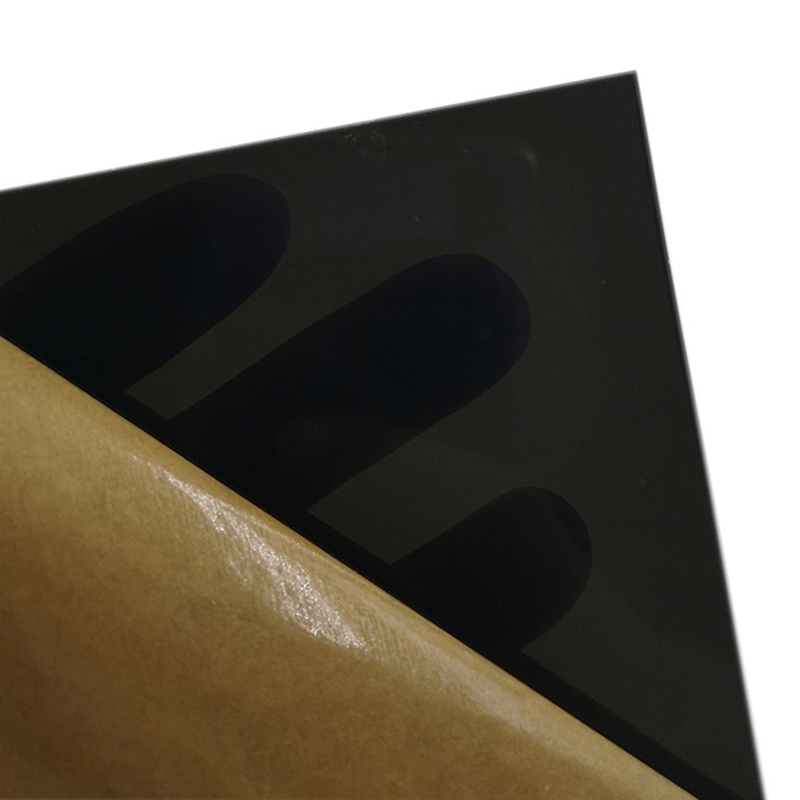

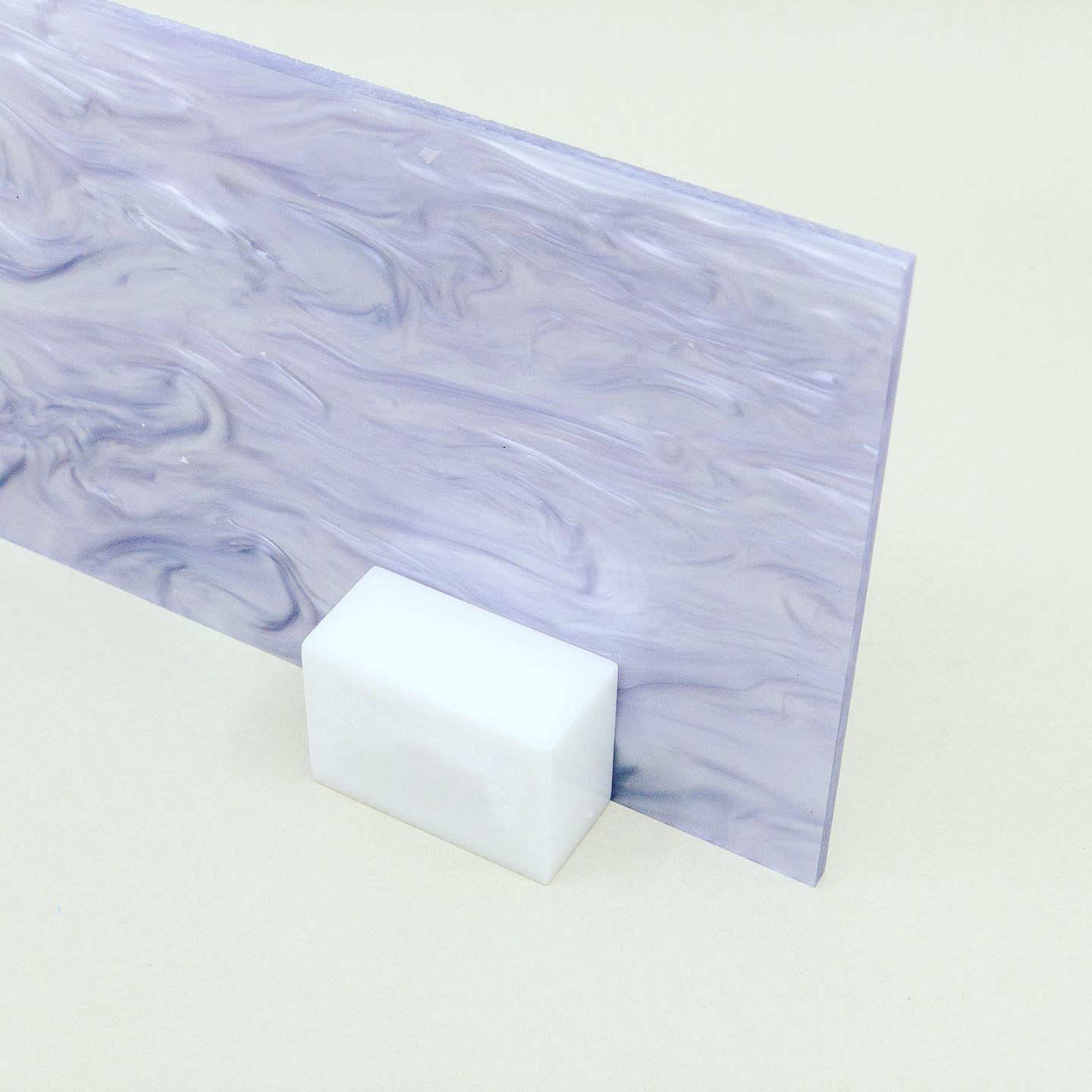

7. Customizability

Acrylic can be easily molded, cut, and colored, allowing for endless customization. Whether you need frosted panels, mirrored sheets, or tinted windows, acrylic can be tailored to fit your specific requirements.

Applications of Acrylic Sheet Glass

Thanks to its exceptional properties, acrylic sheet glass is used in a diverse range of industries. Here are some of its most popular applications:

1. Retail Displays and Signage

Acrylic’s clarity, durability, and customizable finishes make it ideal for retail displays and signage. It can be used to create sleek, professional displays that enhance a brand’s visibility.

2. Aquariums and Terrariums

Acrylic’s high transparency and impact resistance make it a preferred material for aquariums and terrariums. It can withstand significant water pressure without compromising visibility.

3. Protective Barriers

In the post-pandemic era, acrylic has become a go-to material for protective barriers in retail, healthcare, and office environments. These barriers are durable, easy to clean, and visually unobtrusive.

4. Greenhouse Panels

Acrylic panels are used in greenhouses for their ability to transmit light efficiently while providing superior insulation. Their UV resistance ensures they remain clear and effective for years.

5. Skylights and Windows

Acrylic skylights and windows offer a lightweight, shatter-resistant alternative to glass. They are commonly used in residential, commercial, and industrial buildings.

6. Bullet-Resistant Glass

Acrylic can be layered and treated to create bullet-resistant glass, which is used in banks, government facilities, and security vehicles.

Benefits of Acrylic Sheet Glass

Choosing acrylic over traditional materials comes with numerous advantages, including:

- Affordability: Acrylic is cost-effective compared to glass and other materials, making it accessible for a wide range of projects.

- التنوع: Its ability to be molded and customized means it can suit almost any application.

- متانة: Acrylic’s resistance to impact, UV rays, and chemicals ensures a long lifespan, even in demanding environments.

- Sustainability: Acrylic is recyclable, which makes it a more environmentally friendly choice.

خاتمة

Acrylic sheet glass is a remarkable material that has transformed industries and empowered designers, engineers, and hobbyists alike. Its versatility, durability, and affordability make it an ideal choice for countless applications, from aquariums to retail displays and protective barriers.

Whether you’re working on a large-scale industrial project or a small DIY endeavor, acrylic’s unique properties ensure that it will meet your needs and exceed your expectations. As technology continues to advance, acrylic’s role in modern manufacturing and design is only set to grow, cementing its status as a material for all purposes.

If you’re ready to explore the endless possibilities of acrylic sheet glass, now is the perfect time to start. Its combination of functionality and aesthetic appeal makes it a valuable addition to any project.

FAQs About Acrylic Sheet Glass

1. How does acrylic compare to glass?

Acrylic is lighter, stronger, and more impact-resistant than glass. It’s also easier to mold and customize, making it suitable for a wider range of applications.

2. Can acrylic sheets be polished or restored?

Yes, acrylic sheets can be polished to remove scratches and restore clarity. Specialized acrylic polishing compounds and buffing tools are available for this purpose.

3. Is acrylic heat-resistant?

While acrylic can withstand moderate temperatures, it is not as heat-resistant as glass. Prolonged exposure to high heat can cause it to warp or melt, so it’s best to avoid using it near open flames or extreme heat sources.